Smokin

New Member

- Joined

- Sep 8, 2021

- Messages

- 217

It's not an Alternater yet because there is no Diode pack attached to it. It is a Motor/generator.

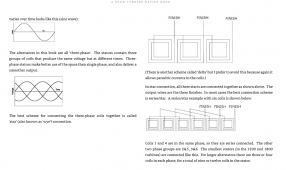

The spinning thing has magnets on it which makes up the thing called an Armature.

The coil thing is called a Stator.

The moving magnets cause current and voltage to flow in the coils. The faster the spinning the higher the voltage. The more torque the more current.

What you have here is a typical 3 phase permanet magnet motor. However this can also be used as a generator. Same thing as Hoverboard motors and ebike motors.

There insanely simple.

This thing is not a 6000 watt motor/generator. But it was cheap and they cool to play with. Instead of feeling ripped off, take the time and study it and you will be better for it. These things are toys. If you get board you can mount it to a bicycle or gocart, off the back and run it on an ebike controller and that would be cool. Mad Max chit rite there.

You could make it into a ceiling fan.

The spinning thing has magnets on it which makes up the thing called an Armature.

The coil thing is called a Stator.

The moving magnets cause current and voltage to flow in the coils. The faster the spinning the higher the voltage. The more torque the more current.

What you have here is a typical 3 phase permanet magnet motor. However this can also be used as a generator. Same thing as Hoverboard motors and ebike motors.

There insanely simple.

This thing is not a 6000 watt motor/generator. But it was cheap and they cool to play with. Instead of feeling ripped off, take the time and study it and you will be better for it. These things are toys. If you get board you can mount it to a bicycle or gocart, off the back and run it on an ebike controller and that would be cool. Mad Max chit rite there.

You could make it into a ceiling fan.

Last edited: