In my case, I had 2 ways of solving this. On my 12v RV system I'm building, I just went with 8 cells instead (ouch), so I could just buy 2x OverKill 120a 4s BMS, and keep them as separate 4s banks in 2P, then that gets me the 240a, with known tested and good low-temp cutoff.

Now obviously that is twice as expensive, perhaps why you are only trying to use 4x cells (or may be space related), I understand potential budget constraints, no worries. However, if you did have it in budget or within space constraint, the 8x does give double the runtime, and bank redundancy.

So on my other 48v system I'm building, the issue is that the 2x 200a 16s BMS that were included with those battery systems, they do not have low temperature cutoff (didn't learn that until after the fact). So I decided to get a Victron MPPT charge controller, with a Battery Sense monitor w/ temp probe (or you can alternatively use their BMV monitors w/ temp probe, or the Smart Shunt monitors w/ temp probe), and the Victron will be the one monitoring for low temp and do the charge cutoff at desired temp.

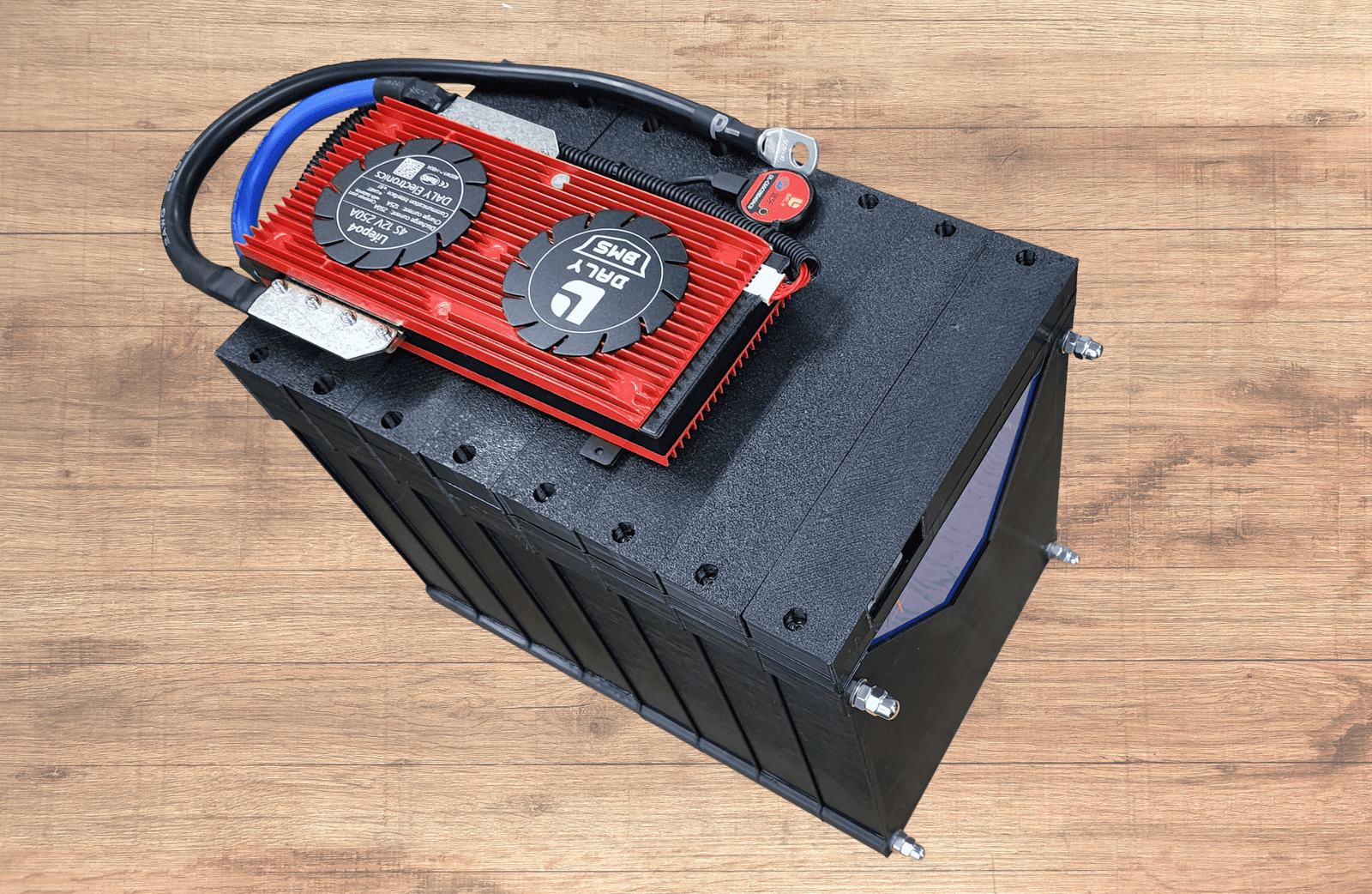

Other note, I did read today somewhere here, that maybe some of the newest Daly BMS may support low temp cutoff (find someone who tested it and confirms it works):

https://diysolarforum.com/threads/daly-high-current-question.13558/#post-161850

(keep in mind this guy who said it works is using a 100a one)

Chargery low temp cutoff might work too (not sure the amps ratings or if they have 4s ones)..

Good Day Folks ! Note: I have no affiliation with Chargery whatsoever, I'm just a customer sharing info in the best interest to help others. I purchased a Chargery BMS8T a month or so ago as a replacement BMS for my ShunBin pack. Post showing installation on ShunBin Pack The installation has...

diysolarforum.com

Or keep searching on AliExpress and see if you can find a high amp BMS where the seller says low temp cutoff works (although still not tested, and cross fingers).. Also, even if they say the low temp cutoff works, is it user-configurable setting? Like doe it have Bluetooth and is a managed BMS? My OverKill BMS are managed so there is a user setting to change the temp. On my other BMS's, even if it were to have a working low temp cutoff say, that BMS is not manageable, so the parameter would be hard set and locked into whatever the manufacturer thought was a safe charging temperature...

According to the videos I've seen from Will, there are several instances where he would test BMS where they were advertised as working low temp cutoff, then he would test the feature and it wouldn't actually work. So in my case, that is why I opted for the OverKill one, because Will endorses them and tested that they do work, and this is a keystone point about OverKill BMS's. With other vendors it can be hit/miss, so you almost have to find someone who tested it and says it works for sure, then get the same model number yourself, otherwise it may be a gamble.

But again, the other option is to just let the charge controller handle it, if it offers the option, and with Victron, it requires the external temperature probe to get realtime temp monitoring, as the internal temp probe in the Victron only takes a reading once a day or something like that.