When you say ‘no terminal movement’ does that mean the bottom is expanding by an average of 0.65mm but the top (where the terminals are) is not?

The top springs are moving, but the terminals aren't moving in relation to each other.

When you say ‘no terminal movement’ does that mean the bottom is expanding by an average of 0.65mm but the top (where the terminals are) is not?

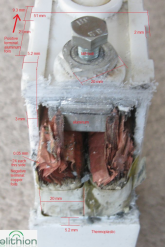

70% SoC. 0.4, 0.7, 0.6, 0.9mm spring movement. No terminal movement.

The downside is, this increases the overall length by 2 inches. I'll have two rows of 4 so that's another 8 inches per row. I think I have the space for that but I'll need New Horizons to do some measurements for me. It again makes me think about using 8 cells per fixture...

Do you have numbers behind the compression concept? I was just planning to bolt mine up but I am curious about the need for spring loading.

In mine, I've added some PEX around the allthread to protect the batterys from rubbing on it. (yes I read the flex numbers, I'm more concerned if I need to allow for cell movement)

From what I can see, the biggest concern is terminal movement delta from the pack postion. I'm thinking that flexible bus bars -calb style or just terminated cables is likely sufficient. It's still a significant investment in battery pack, so I'm certainly interested as I'm pretty close to battery installation on mine. (Today it's a tesla module, soon to be the 16x 280ah cells)

So you used 16 of those $4 springs? How many per pack (single-row)?Just purchased 16 springs: https://www.leespring.com/compression-springs-hefty?search=LHL625D03

I guess I'm going to try 4 packs of 8. Time to start working out so I can lift these 95-100lb suckers. ?

So you used 16 of those $4 springs? How many per pack (single-row)?

What I mean is if you were going to use these springs for a 4S or 8S pack with all of the cells abutting in one row, how many Springs would you use, 4? 8?

Thanks.4 per pack, regardless of 4s or 8s -- it can handle both because the fully-compressed set of 4 springs is 728 pounds and subtract 4mm for 8 cells (0.5mm each) or 0.15748 inches at a spring rate of 380 pounds per inch so 60 pounds per spring or 240 for all 4 .. which means 0% SoC is at 728 - 240 = 488 pounds. 728 pounds = ~13.5 PSI and 488 pounds = 9 PSI. I plan to back off the spring a little so I'm closer to 8.5 at 0% SoC and 12.5 PSI at 100% SoC.

Thanks.

So I understand you are using 5 springs per pack and that each spring applies 182 lbs fully-compresssd (since 4x182=728lbs).

And I understand that from that fully-compressed state near 100% SOC, you are assuming 0.5mm compression per cell (so each spring will expand 8x0.5mm = 4mm at 0% SOC).

And by ‘spring-rate’ I believe you mean the force applied by each spring will reduce from it’s maximum of 182 lbs fully-compressed at a rate of 380 lbs per inch meaning that after expanding 4mm = 0.1575”, each spring will have been reduced by 60lbs to 122lbs remaining (so 488 lbs remaining in total at 0% SOC).

What I’m not understanding is what is the maximum travel of the spring at this spring-rate of 380 lbs /inch? Is it 182 lbs / 380 lbs-per-inch = 0.479” (12.17mm)?

And also, how confident are you of the 0.5mm per cell travel figure is correct? I’ve seen others claim travel if 0.75mm / cell or even 1.0mm / cell between 0% SOC and 100% SOC.

Could it be that those larger numbers were measured on the first charge/discharge cycle under pressure and you are getting this lower number after completing several cycles?

I started going down the Belleville washer route but had problems with inexpensive washers getting caught on threads, so when I look at the cost of more expensive washers versus the $16 needed for 4 of these, between being cheaper and easier because of no issues with threaded-rod threads, I’m starting to re-evaluate...

Shipping to the Bay Area is only $6.40, so not that big of a deal. But for orders under $40 there is a $20 ‘handling fee’ which is a showstopper for me.You've got it!

This particular spring can travel 0.5 inches. The rate is constant.

I have repeatedly measured a maximum of 2mm of movement in a 4s configuration. The first run of 100% to 0% SoC will result in larger movement but after that, I've not seen more than 2mm.

Note that they charge shipping if you only order $16 worth.

The point of the compression is to prevent the cells from bloating .... and at the same time add to the cycle life of the battery .... if the compression is in the correct range.I dig the spring solution, but has anyone considered just spacing the cells out? If we were to add a spacer that's like 1/8 inch thick between each cell, and cut out the middle so that it's maybe 1/2 inch around the edges of the cell, wouldn't that allow for the expansion?

Just a thought...

he point of the compression is to prevent the cells from bloating