Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,498

Rubber feet, even if bolted to the floor, would flex several mm.

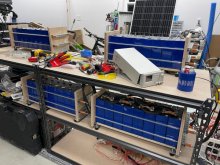

You could wrap a ratchet strap around the pack and secure it to eye bolts or whatever. I did that for a spare tire and milk crate organizer in the back of my hatchback, figuring if it ever flipped end over end I'd be better off without heavy projectiles inside. I've similarly wrapped a strap around my home battery bank so it doesn't try to rip cables out of inverters if we get an earthquake.

You could wrap a ratchet strap around the pack and secure it to eye bolts or whatever. I did that for a spare tire and milk crate organizer in the back of my hatchback, figuring if it ever flipped end over end I'd be better off without heavy projectiles inside. I've similarly wrapped a strap around my home battery bank so it doesn't try to rip cables out of inverters if we get an earthquake.