Cheap 4-life

My body is 2.63 trillion volts, .07v per cell

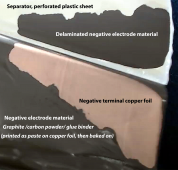

You seem very knowledgeable regarding this issue. More knowledgeable than I am. but from numerous sources, I have seen how much cells expand. That’s from normal/low c-rates and not over charging. Sometimes it’s a lot more than 2mm or at least it looks like moreThe negative electrode graphite, which is about 20% of cell, expands by 9-11% of its volume between zero and 100% state of charge.

That amounts to less than 2 mm thickness change on a 280 AH cell. Barely noticeable.

Last edited: