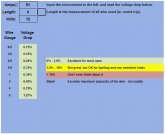

I need to run wire from my converter to the bus bar. The one-way distance for one of the wires from the converter to the bus bar will be no more than 20", perhaps a bit less depending on how I route the wire. One wire gauge calculator says that 6 AWG is OK to use. That makes me happy since I have either 6 AWG or 2/0 AWG (2/0 won't fit in the converter ports so that's not going to happen). The wire calculator on the Bay Marine Supply website disagrees, saying that not even 1 AWG is acceptable.

Similarly, my 1000 watt 12v inverter needs wire also. The distance for that is a few inches shorter, but also includes a circuit breaker. I calculated that the maximum amperage throughput for the inverter would be 91 amps (1000 / 12 * 1.1). The manufacturer says the inverter is 85%-90% efficient. I'm optimistic and going with 90%. I don't push this inverter very hard. I previously had 6' of 1 AWG when the inverter was in a different location.

The distance from the bus bar to the battery is no more than 20". The bus bar to battery wire is 2/0 with all the necessary disconnects and fuses. This is a 12v system.

I thought I had this all figured out.

I need this system up and working in four days. I don't have time to get different cable. If the 6 AWG is acceptable that would be great. Otherwise, I'll try to make the 1 AWG work. It's very stiff wire so it's difficult to work with in small spaces.

Similarly, my 1000 watt 12v inverter needs wire also. The distance for that is a few inches shorter, but also includes a circuit breaker. I calculated that the maximum amperage throughput for the inverter would be 91 amps (1000 / 12 * 1.1). The manufacturer says the inverter is 85%-90% efficient. I'm optimistic and going with 90%. I don't push this inverter very hard. I previously had 6' of 1 AWG when the inverter was in a different location.

The distance from the bus bar to the battery is no more than 20". The bus bar to battery wire is 2/0 with all the necessary disconnects and fuses. This is a 12v system.

I thought I had this all figured out.

I need this system up and working in four days. I don't have time to get different cable. If the 6 AWG is acceptable that would be great. Otherwise, I'll try to make the 1 AWG work. It's very stiff wire so it's difficult to work with in small spaces.