BMc

New Member

- Joined

- Feb 20, 2020

- Messages

- 6

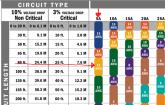

I'm new to the forum and a solar newbie, however I'm technically competent. I've not been able to find some answers on the internet and after reading the thread on fusing, I'm hoping you can help me out. I'm building a small house (230 sq ft) and will run 7 10 watt DC LEDs (on 3 circuits) from a 12v battery. I will also have a separate AC system. My original plan was to install the DV fuse box close to the battery and run 6 wires for the 3 circuits to the light switches from there. That distance is approx. 30' using awg 10 wire. However it would be more convenient to run 2 wires from the battery to the 12v fuses mounted next to the AC breaker box and then to the 3 lighting circuits. So my questions are:

Does it mater where the fuse box is located in a DC only system.

What wire size is normal for the battery connections to a DC (solar) fuse box? I'm assuming they're basically the same as uses for autos or marine.

If I do change the location, will I require larger than awg 10 wire for the 12' cable run? Related to my previous question how big are the connection points on a DC fuse box?

Thanks in advance BMc

Does it mater where the fuse box is located in a DC only system.

What wire size is normal for the battery connections to a DC (solar) fuse box? I'm assuming they're basically the same as uses for autos or marine.

If I do change the location, will I require larger than awg 10 wire for the 12' cable run? Related to my previous question how big are the connection points on a DC fuse box?

Thanks in advance BMc