automatikdonn

Becoming Offgrid

Yea I agree, I even made sure I said that in the video. This circuit could support a momentary switch easily. You might not need all of the extra when you use a push button though.Nice @automatikdonn- looks like #177 video is an implementation of the blind bootstrap method of #161 with clever use of the 2s delayed-on timer within the 240v (and 120v) over/under voltage protection device (for those who may not be familiar with that feature). Even though the delay-on feature of this circuit does cold-start the system, I'm really concerned that there is no stop/failure criteria. That 240v protection relay will continue to send voltage to your 240v loads panel even if the system fails to bootstrap. I think this could be improved by replacing the 240v protection relay with a simple timer board. I dunno about that specific timer board, but I've got a few of these and some of them have like 20+ different built-in functions with user configurable params, and I'm almost certain the blind bootstrap would be satisfied by one of them. Doing so would bound your error and permanently de-energize the AT if bootstrapping failed.

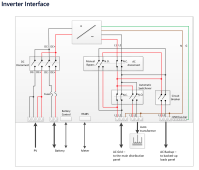

Here's an example of how it'd look, the way I'd do it:

This is the system I'd recommend to people who feel the unlikely risk of AT failure is offset by the benefit of a system that automatically starts. Anybody else, I'd recommend human-in-the-loop cold start only.

- GW on-grid. 240v on AC OUT, AT powering 120v loads, all systems go.

- Grid failure. GW ATS transitions to off-grid. Temporary loss of 240v on GW AC OUT.

- GW AC OUT comes back online after a couple seconds. Timer circuit is energized by N/C poles of main 240v loads panel contactor (same circuit that powers your 240v over/under protection relay). Timer executes one-shot cold start logic (goes high for ~6s, then goes and stays low), ending the sequence on a logic low, and remaining there as long as it continues to receive 240v from GW AC OUT

I personally know I won't be happy until I have the temp sensor of the AT instrumented, so I'm fixin to implement #159. I think this design scales to automated control most elegantly, and right now we have no way I can think of to read the AT thermocouple outside of a 3rd party temp controller or similar. I picked up a chip that converts K-type thermocouples to SPI bus readings. Gonna take some time to integrate to a NodeMCU/etc but if it works I'm happy to open source the code and process. I think this system beats the safety of even human-in-the-loop cold starting, and it's automated.

We need to find an automated one time switch or programmable method to track the number of bootstrap attempts.

The circuit is really no different than a hard wired direct connect of 240v to the contactor and no safer.

I wanted to mostly show people how easy and flexible contactors are. Maybe even spark an idea on how we solve that one shot issue. I don't know of any way that doesn't involve an externally or battery powered logic controller