Hello All,

I have no experience with solar, but have been watching lots of videos and doing a lot of reading here on the forum and elsewhere. I am designing a system for my camper van. I expect to consume up to 3000wh/day but more like 1500wh most days. So the battery is sized to store excess capacity for cloudy days, and higher use days. The van will mostly be used in the southwestern US April - September, and any possible winter time use would be in Mexico or further south. The largest load I expect to put on the system is an induction cooktop that can draw 1800W, though I don't expect to be using both burners on full blast very often.

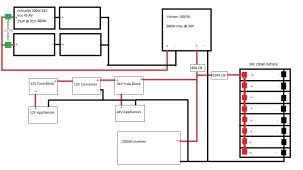

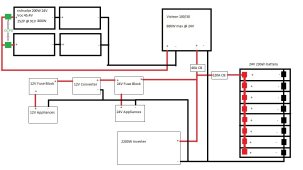

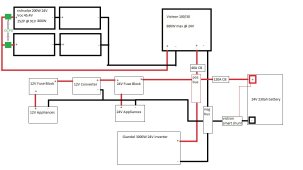

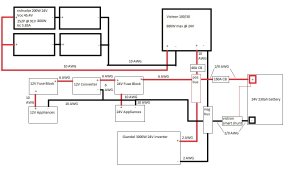

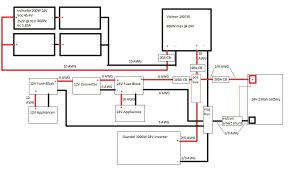

Please take a look at my diagram and tell me what you think. Any suggestions and/or guidance is very much appreciated!

I have no experience with solar, but have been watching lots of videos and doing a lot of reading here on the forum and elsewhere. I am designing a system for my camper van. I expect to consume up to 3000wh/day but more like 1500wh most days. So the battery is sized to store excess capacity for cloudy days, and higher use days. The van will mostly be used in the southwestern US April - September, and any possible winter time use would be in Mexico or further south. The largest load I expect to put on the system is an induction cooktop that can draw 1800W, though I don't expect to be using both burners on full blast very often.

Please take a look at my diagram and tell me what you think. Any suggestions and/or guidance is very much appreciated!

Attachments

Last edited: