severin20

New Member

- Joined

- Jun 18, 2020

- Messages

- 28

Hello,

My name is Severin and this is my first ever solar install.

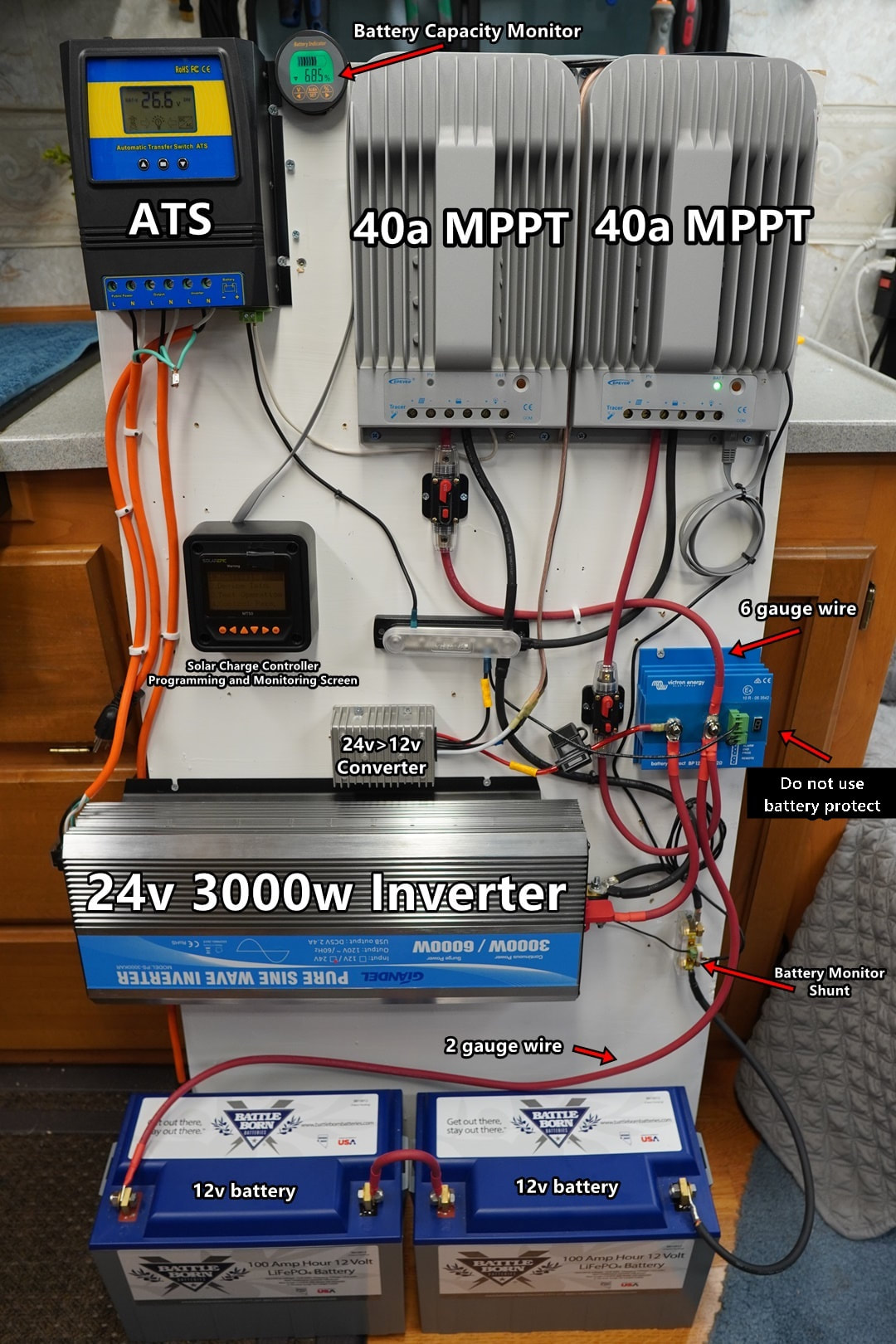

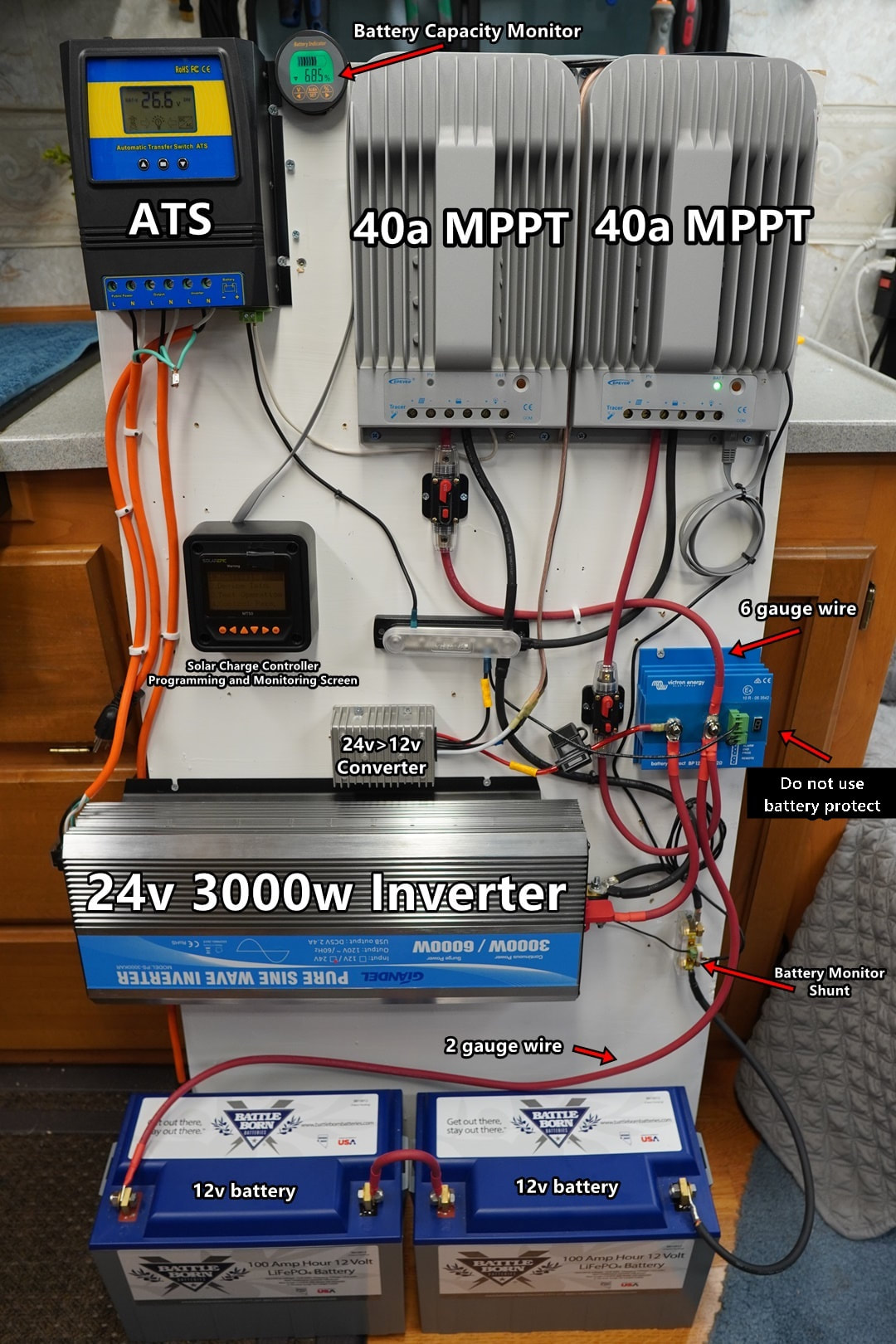

I purchased everything recommended for the 24V 4000 watt system as shown here.

My question is how do I connect 4000watts to the 40amp charge controllers that I have 2 of.

I got 16 panels at 250watts each. Hoping to wire 8 of them into one charge controller and 8 of them into the other controller.

The panels are 24v with the following specs:

EPEVER MPPT Solar Charge Controller 40A 150V PV Solar Panel Controller. more info about the charge controller is here:

https://amzn.to/3006KTl

Should I wire 4 panels in parallel, and then 2 of those groups in series to make 8 panels that go into a charge controller?

Any help would be greatly appreciated. My kids get back from their grandparents in 3 weeks so I have a little time to figure this out, but if I don't we got no power! well i guess i'd buy a gen

My name is Severin and this is my first ever solar install.

I purchased everything recommended for the 24V 4000 watt system as shown here.

RV Solar Power Blue Prints

Building a vehicle mounted solar power system? Let me help.

www.mobile-solarpower.com

My question is how do I connect 4000watts to the 40amp charge controllers that I have 2 of.

I got 16 panels at 250watts each. Hoping to wire 8 of them into one charge controller and 8 of them into the other controller.

The panels are 24v with the following specs:

- Rated Power: 250W

- Open circuit voltage (VOC): 37.6 V

- Max power voltage (VMP): 30.3 V

- Short circuit current (ISC): 8.85 A

- Max power current: 8.27 A

EPEVER MPPT Solar Charge Controller 40A 150V PV Solar Panel Controller. more info about the charge controller is here:

https://amzn.to/3006KTl

Should I wire 4 panels in parallel, and then 2 of those groups in series to make 8 panels that go into a charge controller?

Any help would be greatly appreciated. My kids get back from their grandparents in 3 weeks so I have a little time to figure this out, but if I don't we got no power! well i guess i'd buy a gen