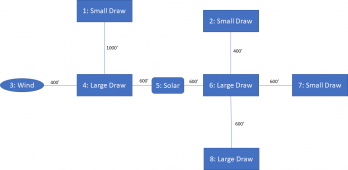

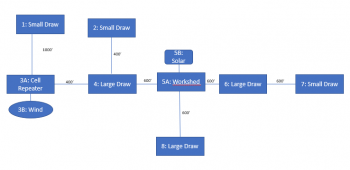

without using high voltage I don't see an economical way to connect them together

The problems with the long distances is the voltage drop and energy loss. You might decide to live with the energy loss but the voltage drop may be too much. You really only have a few options.

1) High voltage and low current with small cables.

2) Low voltage and high current with monster big cables.

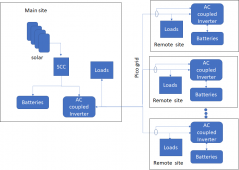

However, there may be a hybrid AC-coupled solution that could help.

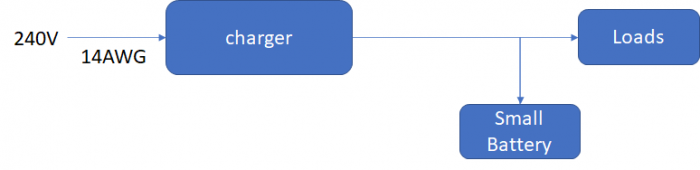

Let's say you put a complete system with solar, batteries and an inverter at site one but only had batteries and an inverter at site two. You could have 220V run from site one to site two, but at site two the only thing the 220 is connected to is a charger for the batteries at site two. The current from site one to site two could be reasonably low because it only needs to charge at the

average usage rate of site two.... not the full power required by site two. Consequently, the wires between sites one and two could be a lot smaller than if they had to power all of site two. Furthermore, if your charger has a wide range of voltage inputs, you could suffer a reasonable voltage loss (and power loss) before the system stops working.

You would still be putting a lot of equipment at each site, but it may be better than a full system at each site. Since only one site at a time will be used, the batteries at site two may not have to be very large. They only need to be large enough to cover the peak usage because in the off-peak you will be recharging them from the larger batteries at site one.

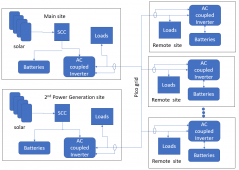

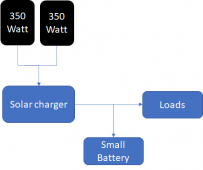

Now let's say you had a wind turbine at site 3. It could drive a small battery bank and a 220V inverter at site 3 that sends power to a battery charger at site one.

There are several things to consider with this idea.

1) Even with the smaller wires, the cost of the copper between the sites might still be higher than it would be to have independent systems.

2) Converting the power to AC, sending it down the wire, and then converting it back to DC is not very efficient. Your solar array will need to be large enough to cover this inefficiency.

3) If 220V is 'high voltage' to you, you could do the same kind of thing with 120V, but the wires will need to be larger.

4) six sites and six inverters will draw a LOT of idle currents. Ideally, you would shut down the inverter at the sites you aren't using.

Alternatives to shutting down the inverters and not having power at the unused sites:

- You could have a smaller inverter that you switch to when to location is not in use.

- If the background idle consumption of the house is low enough, you could switch to using the 220V coming from site one when the house is not in use

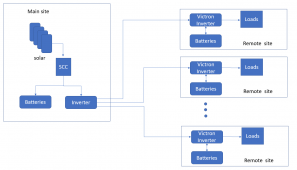

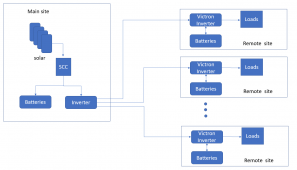

With Victron inverter/chargers that have AC Boost from the batteries, you could build an interesting system.

You can tell the Victron the max current to draw from the AC-in. (let's say you set it to 5A). If the loads exceed 5A, the Victron will supplement with power from the battery. When the loads are less than 5A, the Victron will start charging the battery.

Since the remote site is getting a continuous 220V at 5A, the site will have up to 5A * 220V *24hr = 26.4KWhr to use each day (Assuming the batteries at the remote site can hold that much). That is a lot of energy so maybe you could set the input current limit to something smaller. Some planning will be needed.

=================================

I feel like there might be another solution with AC-coupled inverters, but I don't have enough experience with AC coupling to say what it would be. However, if you could produce a similar solution with AC coupling where the site-to-site current is always low, it would be very slick. The AC coupling would be bi-directional so at any given time a site could be providing power or could be using power. This way, whatever site you are using can be drawing off the batteries of all the other sites.