Donlumber

New Member

- Joined

- Sep 10, 2021

- Messages

- 32

I needed a way to store and move my 24v 280ah battery pack between my house and travel trailer. I searched all over for an enclosed cart with wheels and finally settled on a Husky brand box. I used 3/8" threaded rod to hold my batteries between 3/4" plywood and 1" square tubing.

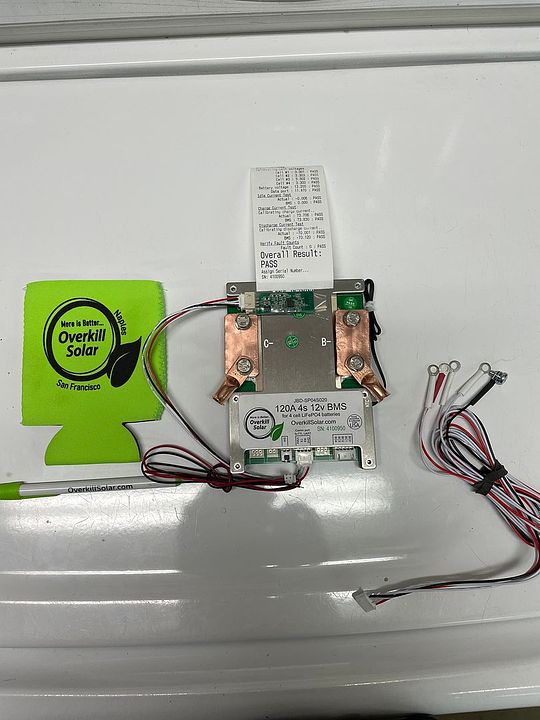

I sandwiched 1/4" resilient foam between the cells and between the plywood. It's rated for 11psi to compress 25%. I still need to mount a shelf so I can mount the BMS, fuse and bus bars. I'll be using Anderson power connectors to connect this battery pack to my Titan solar generator.

One thing I checked after the cells were compressed is if the stock bus bars that came with them would straddle the extra width. Nope. Thankfully the flexible bus bars I purchased work just fine.

I still need to trim the threaded rod too. I'll post my progress in case anyone is interested. I plan to cover everything with acrylic.

I sandwiched 1/4" resilient foam between the cells and between the plywood. It's rated for 11psi to compress 25%. I still need to mount a shelf so I can mount the BMS, fuse and bus bars. I'll be using Anderson power connectors to connect this battery pack to my Titan solar generator.

One thing I checked after the cells were compressed is if the stock bus bars that came with them would straddle the extra width. Nope. Thankfully the flexible bus bars I purchased work just fine.

I still need to trim the threaded rod too. I'll post my progress in case anyone is interested. I plan to cover everything with acrylic.