I haven't found a clear thread on this or my search ability is a bit lacking.

In contacting the design team at Signature Solar I was planning on purchasing the EG4 6.5kW Off-Grid Inverter, with 2 EG4-LL Lithium Battery (V2) | 48V 100AH and the Nader DC Circuit Breaker | 60V 200Amp. The quote had the 84in 1 AWG Battery to Inverter Cables | Black and Red which I also see on the set of 2 6500's.

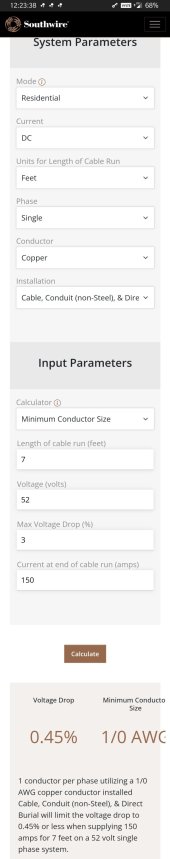

I am concerned that the 1AWG is too small. In the manual on page 12 it states

Typical Amperage 153A

Minimum Wire Size >1/0AWG or greater than.

I did call but can't reach the design team via the phone so I spoke with support and he said 2/0AWG is the minimum he recommends.

So why does Signature Solar quote and include in their sets 1AWG which is below the recommended spec? And would it be fine to accept that? This is my only concern before making the purchase. I did email the one from the design team I was working with but either she is off for a few days or doesn't want to answer my email.

In contacting the design team at Signature Solar I was planning on purchasing the EG4 6.5kW Off-Grid Inverter, with 2 EG4-LL Lithium Battery (V2) | 48V 100AH and the Nader DC Circuit Breaker | 60V 200Amp. The quote had the 84in 1 AWG Battery to Inverter Cables | Black and Red which I also see on the set of 2 6500's.

I am concerned that the 1AWG is too small. In the manual on page 12 it states

Typical Amperage 153A

Minimum Wire Size >1/0AWG or greater than.

I did call but can't reach the design team via the phone so I spoke with support and he said 2/0AWG is the minimum he recommends.

So why does Signature Solar quote and include in their sets 1AWG which is below the recommended spec? And would it be fine to accept that? This is my only concern before making the purchase. I did email the one from the design team I was working with but either she is off for a few days or doesn't want to answer my email.