TerryTtibbs

New Member

- Joined

- Mar 15, 2022

- Messages

- 56

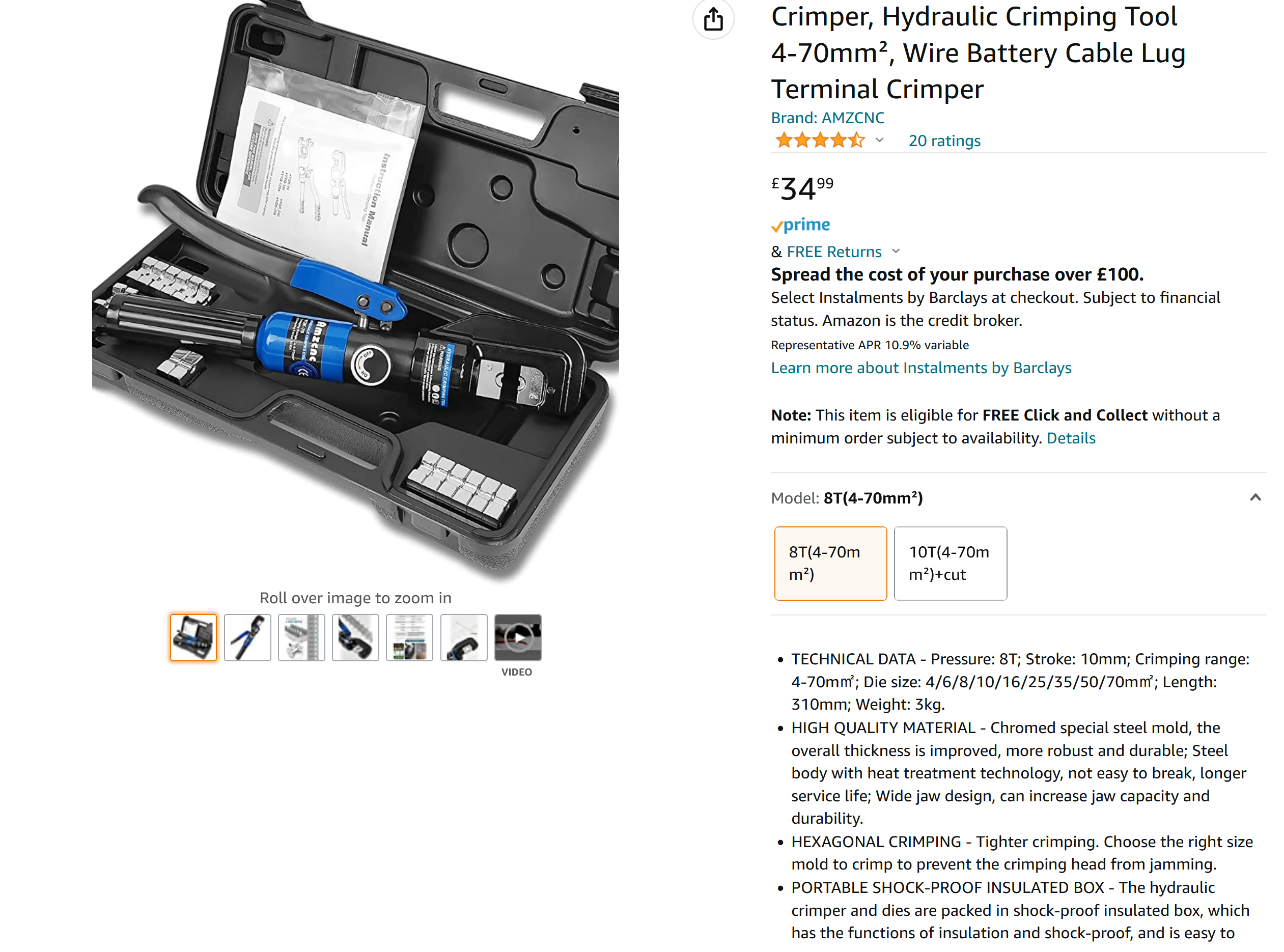

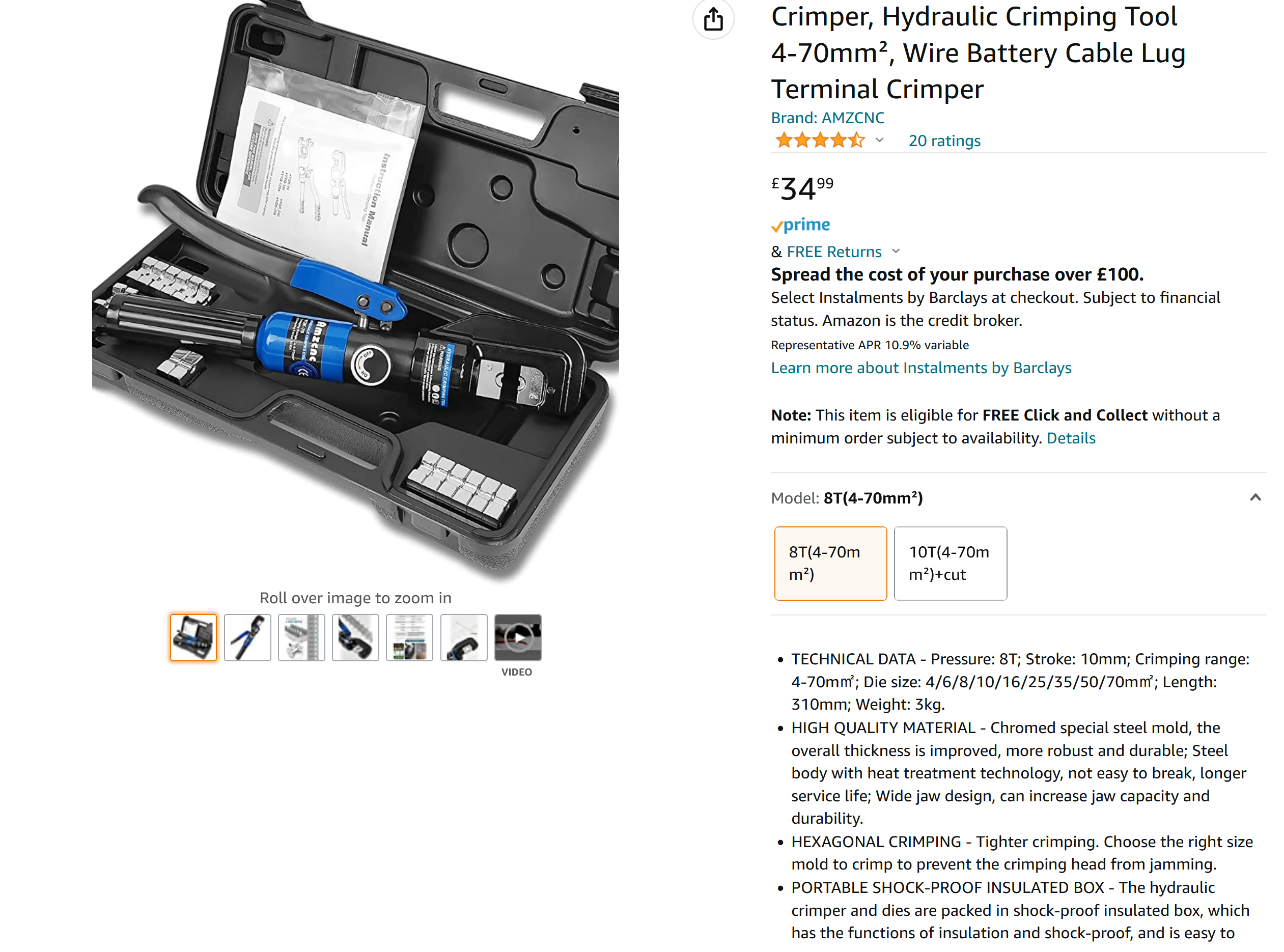

Elcheapo Hydraulic Hex crimper results, as expected...stick to Burndy mechanical indent crimps eh!

$50 Amazon hydraulic crimpers.

Metric 35mm copper lug Be stamped.

35mm copper 1500VDC cable.

Cut carefully with a dremel grinding wheel. Was a bit eager in the first half of the cut so the grinding wheel anealed a bit, but the second half of the cut was nice and slow.

These are the results.

In summary probably 20% less CCC with a few months of corrosion than the rated cable probably leading to some kind of firework display if pushed hard with a 3KW+ peak invertor.

Im sticking to my Burndy Dieless Ident crimpers for guaranteed pressure crimp each time.

Just thought I would try them as plenty of Ben Shillers on YT pushing them hard.

Wouldn't be putting these to use on any of my gear unless its bonfire night!

$50 Amazon hydraulic crimpers.

Metric 35mm copper lug Be stamped.

35mm copper 1500VDC cable.

Cut carefully with a dremel grinding wheel. Was a bit eager in the first half of the cut so the grinding wheel anealed a bit, but the second half of the cut was nice and slow.

These are the results.

In summary probably 20% less CCC with a few months of corrosion than the rated cable probably leading to some kind of firework display if pushed hard with a 3KW+ peak invertor.

Im sticking to my Burndy Dieless Ident crimpers for guaranteed pressure crimp each time.

Just thought I would try them as plenty of Ben Shillers on YT pushing them hard.

Wouldn't be putting these to use on any of my gear unless its bonfire night!

Attachments

Last edited: