Something to be aware of when using metal cases of any kind to house the cells. The cell is wrapped with PVC material. Underneath is the aluminum case for the cell. The aluminum case is positive. So if something on the metal case the cells are housed in pierces the PVC and makes contact with the aluminum cell case, the metal case will become positive. And if the metal case makes contact with ground that will not be good unless the case is kept isolated from ground, as well as anything mounted to it that might have ground connected through a screw or something.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

EVE 280 Amp Cells in 12V Pack

- Thread starter Opie91

- Start date

i have to say you have some really nice beefy cables. i only used 2x6mm2 however max ill pull is 50A so should be fine. temp only raises 1.C when running at full load for an hour. ya did make the clamping system allot better than me. i just used an sort of wooden case with some bolts which move a plate to the cells. it works but i think yours is way more durable. maybe ill rebuild mine one day. But great job on the battery

3D printed a bracket that matched the BMS and put screws through it all. Worked out pretty good. I'm building a second pack but make a new bracket that will hold the BMS with the wires already soldered on.

I am finding that the BMS takes 50 amps until the battery is depleted and barely rises above room temp with the stock wires. No way I will consistently draw 50 amps for more than it takes to warm a burrito in a microwave.

Something to be aware of when using metal cases of any kind to house the cells. The cell is wrapped with PVC material. Underneath is the aluminum case for the cell. The aluminum case is positive. So if something on the metal case the cells are housed in pierces the PVC and makes contact with the aluminum cell case, the metal case will become positive. And if the metal case makes contact with ground that will not be good unless the case is kept isolated from ground, as well as anything mounted to it that might have ground connected through a screw or something.

Not worried about that. I actually spent a lot of time keeping that exact senario from playing out. The box is all plastic and a proper marine battery case. The only thing that comes out of the box is the conductors.

Also the cells have spacers top and bottom and keep cells separated .2" apart. Fits just right on the cell. Gives about .1" of space top and bottom and allows you to get to the terminals no problem.

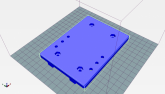

All U channels & threaded rods that come in contact with cells have vinyl tubing on them for insulation and help keep everything in place. 3D printed the spacers.

i have to say you have some really nice beefy cables. i only used 2x6mm2 however max ill pull is 50A so should be fine. temp only raises 1.C when running at full load for an hour. ya did make the clamping system allot better than me. i just used an sort of wooden case with some bolts which move a plate to the cells. it works but i think yours is way more durable. maybe ill rebuild mine one day. But great job on the battery

Yeah those cables look great, and the connections too. Did you do that yourself or did overkill modify the BMS for you?

Yeah those cables look great, and the connections too. Did you do that yourself or did overkill modify the BMS for you?

I ordered the BMS without wires from Overkill. He said #10 screws fit in the holes. The one thing I do not like is at lower amperage ranges the top and bottom cables carry about 50% more load than the center one. I belive that has everything to do with contact area. The center hole has much less contact area.

Where did you get your battery studs from?

If you are talking about the grub screws and nuts for bus bar than look here:

M6 Serrated Flange Nuts

M6x20mm Grub Screw

If you are talking about the negative post than those came from Amazon:

Insulated Battery Post

If you are talking about the grub screws and nuts for bus bar than look here:

M6 Serrated Flange Nuts

M6x20mm Grub Screw

If you are talking about the negative post than those came from Amazon:

Insulated Battery Post

Thank you! I plan on using the screws and nuts from the links you posted.

Sorry I did not. The picture kind of explains everything. I'll list all the parts if that helps you out.I need someone to make this for me, did you happen to document your end to end process for making this?

I'd like to see that list as wellSorry I did not. The picture kind of explains everything. I'll list all the parts if that helps you out.

tehdutchie

New Member

- Joined

- Jun 4, 2020

- Messages

- 31

Same here! Amazing work to see! Thanks for sharing and hope we can replicate it

Built this pack for my Dad's trolling motor out of 190ah cells from BLS. He can fish at least four tides between charges or even go back to the dock with his trolling motor if the outboard had a problem.

The biggest advantage was all the power to weight ratio. The boat is a Boston Whaler 17 Montauk and would have had a hard time carrying enough lead acid to run the trolling motor.

The toughest part is getting him not to charge it every time he gets back

24V Pack

View attachment 20168

Fits in 8D battery box

What material and thicknes did you use for the end plates?

Similar threads

- Replies

- 159

- Views

- 5K

- Replies

- 22

- Views

- 1K

- Replies

- 135

- Views

- 8K