ArthurEld

Solar Wizard

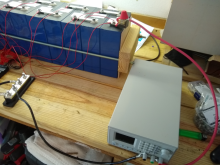

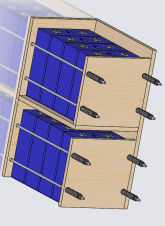

Batteries are the future. I'm going wait until you guys prove out the spring concept then I'll copy yours. ?

I'm still not ready to torque my nuts to 33 inch pounds either.

I'm still not ready to torque my nuts to 33 inch pounds either.