I missed the part about "jellyroll"

One thing many seem to forget is that the cells are 72mm at the edges, but 71 in the center.

Shaped like this )(

All the springs and other solutions need to place pressure at the center, not the edges.

The center goes from )( to [] the 72 edges stay 72.

One could stack the cells, but need something like mention before , closed air "balloon" or some form of gel like silicone.

It should be firm/ rigid enough to give the 300kgf , and flexible enough to spread out over the whole surface.

)(*)( Where the * is the gel/silicone that will get flattened during the expansion of the cells going to from 71 to 72mm at the center.

Or..

If no compression on the center at start, but prevent expansion beyond the 72mm aka bloating/ delaminating.

If you want to use springs, you need 2 springs per cell, pressing at the center ~)(~

Having more cells stacked...

~)()(~. The 2 cell sides on the outside do get the compression force.

The joint between 2 cells getts no compression!!

That will have a gap of 1mm when empty and 0mm when fully charged.

If the cell wants to expand beyond the 72mm, yes, it does stop them, depending on strength of the springs.

A firm ball of some kind, once between the cells, eclipse shape, would be the best solution.

It get flattened, going from 1mm thick to minimal during the expansion.

I don't know what material can stretch out over the whole surface and still be rigid enough to give the compression force with empty cells.

Elastic, really flexible, rigid, and stay elastic during many, many cycles.

Just compression on the sides will do nothing for the extraction at the center who will reach the same 72 mm that the sides already are.

Stopping from going beyond the 72mm..

Yes, springs or whatever..

Just keep it at 72mm

The 71mm at the center, that is a whole different ballpark.

What can compress +/-5000 times without losing integrity?

Syrofoam won't stay good for 5000 times.

I really don't know what is capable of sustaining +10 - 15 years, while being compressed for over 5000 times.

I'm counting every day as a cycle, being used at night, charged at day.

While it probably will spend the most time being flattened, as the cells are mostly full...

It should stay elastic enough to contract itself into the ellipse shape after 100+ days when the cells do get empty enough by accident...

And go from 0.00x mm to ellipse shape of 1mm center distance, providing the 300kgf at that center spreaded out over enough area to not make a dent in the cells..

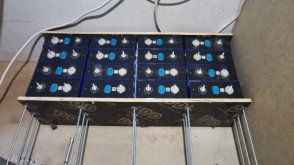

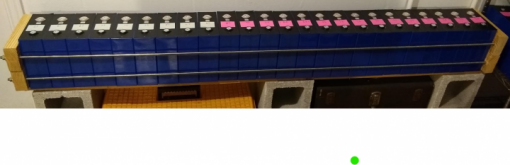

It wont make any difference on how I will install my cells.

Or am installing for the last 4 days.

I don't have that material, so I can't place it between my cells.

They cen expand to the 72, and beyond this... They meet a nice strong plywood sheets, or an other cell who is having more or less the same SOC, the same level of expansion.

Keeping the the pressure at the center so it does have pressure @71mm...

Tell me when you found it

Compression force on both sides, at the center of the cells.. (not just the sides)

Not doable for me.