You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

EVE-280 cells should these be clamped tight or spaced for expansion?

- Thread starter NEWYORKHILLBILLY

- Start date

If you're using compression rods, all-thread for example, just snug them up so the cells can't puff. They don't need actual compression.

Don't over-charge them, don't over-volt them - that will prevent them from puffing in the first place.

Don't over-charge them, don't over-volt them - that will prevent them from puffing in the first place.

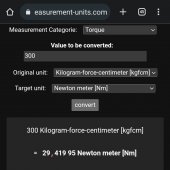

The specification is not torque, it is force. It is 300 kg(force) = ~2938.5 Newtons.Jumping in here...

Is it 300kgf cm or 300kgf m?

If 300kgf cm, the the pressure should be 29,42Nm? That could be done with a torque wrench?

Or am I not reading it correct?

Bergum

New Member

- Joined

- Jul 5, 2022

- Messages

- 16

The specification from EVE is force. You keep saying torque. They are different. You want a constant compressive force.

Bergum

New Member

- Joined

- Jul 5, 2022

- Messages

- 16

The specification from EVE is force. You keep saying torque. They are different. You want a constant compressive force.

A torque wrench is made to tighten a bolt to a certain force.

A torque wrench is made to tighten a bolt to a certain force.Basically when you use this tool, you tighten the bolt so the head of the bolt presses down into the material under with a specified force, measured in Nm.

Therfor i need the conversion....

100 Proof

"Please Lord, don't let me do something stupid."

- Joined

- Feb 14, 2021

- Messages

- 206

Well then you will need to take the diameter of your threads, the material of the fasteners, the pitch of your threads, the number of fasteners you are using, and any lubricant properties involved and do some heavy math to figure it all out to get to 300kgf. It will likely be in the several inch-pounds range. As for me, I just used the k values of my 4 springs and measured how much they were compressed to get to 300kgf.View attachment 101540A torque wrench is made to tighten a bolt to a certain force.

Basically when you use this tool, you tighten the bolt so the head of the bolt presses down into the material under with a specified force, measured in Nm.

Therfor i need the conversion....

There is no simple "conversion" to be had.

A torque wrench is made to tighten a bolt to a certain force.

No, it's meant to tighten it to a certain torque, which is a force applied at a certain distance of the pivot point. Here you're talking about the clamping force, it's not the same thing and it's not a simple conversion, you need the bolt characteristics to convert from clamping force to torque on the bolt (or the opposite)

Force is not measured in Nm, Torque is. Force is measured in Newtons. Trying to calculate force applied to a fastener under a specified torque (*not* specified force) is very complicated. The reason is that the friction is completely unknown. A dry bolt will apply much less force than a lubricated bolt under the same torque. Force and torque are not the same thing.you tighten the bolt so the head of the bolt presses down into the material under with a specified force, measured in Nm.

The next problem you would face in the case of these cells is that your force is correct for exactly one charge value. They tend to expand a bit when they charge, and contract a bit when they discharge. This is due to the lithium ions moving and changing the density of the anodes and cathodes. The force specification is constant, to be applied under all charge conditions.

In my world I have simply placed the cells, four deep, and made them tight without really any compression that I am aware of. I've done this at 85% ish state of charge. My goal is just to prevent them from expanding if they try to. Hopefully this will achieve most of the benefit.

xychix

New Member

- Joined

- Nov 3, 2021

- Messages

- 33

more or less my approach. Clamped all 8 together with 4x m10 rods and plywood at the ends. Used a 17mm socket (without the handle) and hand tied it while the pack was more or less at ~90% SoC.In my world I have simply placed the cells, four deep, and made them tight without really any compression that I am aware of. I've done this at 85% ish state of charge. My goal is just to prevent them from expanding if they try to. Hopefully this will achieve most of the benefit.

Put them in top balancing (flipping half of the cells) and hand tied them again for top balance.

atleast their snug fit at 90-100% soc

Shawn Hayes

Learning Everyday

Same here basically. However I did tighten my “plates” at about 80% SOC to about 8-in lbs. I have rubber mat inside between the aluminum plates and batteries w/ plastic mat separators between each cell.In my world I have simply placed the cells, four deep, and made them tight without really any compression that I am aware of. I've done this at 85% ish state of charge. My goal is just to prevent them from expanding if they try to. Hopefully this will achieve most of the benefit.

Operating parameters between 90% and 20%.

polar ape

New Member

- Joined

- Dec 6, 2021

- Messages

- 12

Force is not measured in Nm, Torque is. Force is measured in Newtons. Trying to calculate force applied to a fastener under a specified torque (*not* specified force) is very complicated. The reason is that the friction is completely unknown. A dry bolt will apply much less force than a lubricated bolt under the same torque. Force and torque are not the same thing.

The next problem you would face in the case of these cells is that your force is correct for exactly one charge value. They tend to expand a bit when they charge, and contract a bit when they discharge. This is due to the lithium ions moving and changing the density of the anodes and cathodes. The force specification is constant, to be applied under all charge conditions.

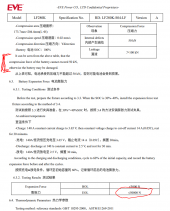

Initial compression force 300kgf has to be applied at ~40%SOC

End of life expansion force should remain under 50kN

Bergum

New Member

- Joined

- Jul 5, 2022

- Messages

- 16

I'm going with 4x 75kg springs.Cool. Now tell us how YOU measure that.

Interesting. Your specification is apparently a swelling force test, not a compression specification for long-term cell use. What does the title sheet say?Initial compression force 300kgf has to be applied at ~40%SOC

The 230Ah cell datasheet I have simply says to keep the cells in a 300kgf fixture. Mine seem happy so far in boxes with Poron sheet providing the compression.

S Davis

Solar Enthusiast

- Joined

- Sep 25, 2021

- Messages

- 564

Four 160# die springs on a single stack works well.Cool. Now tell us how YOU measure that.

Bob B

Emperor Of Solar

- Joined

- Sep 21, 2019

- Messages

- 8,576

This ? ..... seems like the new spec sheets confuse the issue instead of adding clarification.Interesting. Your specification is apparently a swelling force test, not a compression specification for long-term cell use. What does the title sheet say?

Similar threads

- Replies

- 44

- Views

- 3K

- Replies

- 21

- Views

- 1K

- Replies

- 9

- Views

- 313

- Replies

- 30

- Views

- 2K