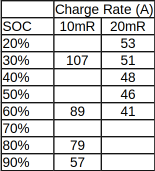

These are the charging rates I have seen with an alternator-battery direct hookup to a 240Ah LiFePO4 battery. In the first case the cables/fuses/connections/shunt add up to around 10mR and in the second case the addition of a resistor bumps it up to around 20mR. The voltage from the alternator sits at around 14.37 at the van battery (prior to the wiring that leads to the 'house' battery).

In my case I am pretty happy with the direct connection. However, I use so little power in summer that the lower rates with the resistor are still more than enough. For folks with lower output alternators, or doubts about the alternator thermal regulation, it seems like the use of a resistor is pretty effective. Although you have to accept lower charge rates at a high state-of-charge it stays surprisingly high up until 90%!

View attachment 41913