The purpose of creating this thread is to discuss the weaknesses of direct FET based BMS control and ways to overcome them using alternate methods, some of which can be addressed by currently available passive BMS's but not entirely

Having collective input towads a common goal is the focus, those who are satisfied with the level of protection their FET BMS offers and see no need to improve don't need to justify their choice by including their rationale to prove a point, everyone is entitled to their respective opinion, but all too often the opinions unrelated to the subject tends to steer discussion of topic.

The FET based BMS is a device many trust to protect their system from the various conditions that could be harmful, for the most part do an excellent job but they have a fundamental flaw, there is never a physical disconnect, they often reconnect automatically to what may have caused the problem in the first place. So many failures can be attributed to such devices, wether caused by the device itself or other externally connected device failure exceeding it's limitations.

Regardless of type, the only time a BMS should intervene in a solar application is when one or more measured parameters is exceeded, the safest means to isolate the battery is physically disconnect from the offending input or output,. To prevent endless reset failure loop manifestation, having a manual reset would be benificial in establishing a fail safe system, a nessersary inconvenience.

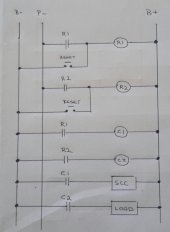

To achieve this with a FET BMS, the output would need to drive an external no resetting relay(s), this would in many cases eliminate some features, such as overcurrent and short circuit protection for example however these can be done externally, albeit with added complexity..

This is in the thought stage, those interested in this concept are most welcome to add comments or ask questions, I'll take some time to think and produce a drawing which I'll post later. This thread is in response to a discussion that began within another thread but off topic, so a little premature.

Having collective input towads a common goal is the focus, those who are satisfied with the level of protection their FET BMS offers and see no need to improve don't need to justify their choice by including their rationale to prove a point, everyone is entitled to their respective opinion, but all too often the opinions unrelated to the subject tends to steer discussion of topic.

The FET based BMS is a device many trust to protect their system from the various conditions that could be harmful, for the most part do an excellent job but they have a fundamental flaw, there is never a physical disconnect, they often reconnect automatically to what may have caused the problem in the first place. So many failures can be attributed to such devices, wether caused by the device itself or other externally connected device failure exceeding it's limitations.

Regardless of type, the only time a BMS should intervene in a solar application is when one or more measured parameters is exceeded, the safest means to isolate the battery is physically disconnect from the offending input or output,. To prevent endless reset failure loop manifestation, having a manual reset would be benificial in establishing a fail safe system, a nessersary inconvenience.

To achieve this with a FET BMS, the output would need to drive an external no resetting relay(s), this would in many cases eliminate some features, such as overcurrent and short circuit protection for example however these can be done externally, albeit with added complexity..

This is in the thought stage, those interested in this concept are most welcome to add comments or ask questions, I'll take some time to think and produce a drawing which I'll post later. This thread is in response to a discussion that began within another thread but off topic, so a little premature.