Ferrules are not same as crimp fit terminals.

Wall thickness is tiny and they don't really maintain much force/crimp on the wire.

Typical 70mm2 ferrule has something like 0.3mm wall thickness and proper crimp terminal has 1.5mm ie. 5x wall thickness.

"

The crimp connections of ferrules cannot be compared directly with connectors or cable lugs. They must be considered differently. Ferrules are used as splicing protection for class 2, 5, and 6 copper wires that are stranded, fine stranded, and extra finely stranded. The copper sleeve of the ferrule has a material thickness of just 0.15 to 0.45 mm. It is significantly thinner than that of cable lugs, for example. If the copper sleeve of a ferrule with a conductor cross section of 2.5 mm² has a material thickness of 0.3 mm, the material thickness of a comparable cable lug is 0.8 mm.

With respect to the crimping of ferrules, DIN 46228 (Part 1 - 4) describes the mechanical testing and overall dimension check starting from 2.5 mm² for class 5 copper wires according to IEC 60228.

The electrical properties are evaluated in association with the later application, e.g., within a terminal block."

Thank you for the link. I find it interesting what you chose to leave out of your quote. Here is the text immediately preceding what you quoted.

"Conductor pull-out test

Crimping points can be affected by tensile forces during wiring or operation. Therefore, properly crimped connectors and ferrules must offer a high degree of mechanical safety. To test the tensile load capacity, a crimped conductor is exposed to a predefined, cross-sectional tensile force for a period of 60 seconds, and it must withstand this load. The tensile force exerts stress on the conductor at the crimping point. Damage to the crimping point must not occur. Generally, even the maximum tensile force is tolerated, until the connection is destroyed.

Description | Language | Updated |

|---|

| english | 03/25/2017 |

Gas tightness of crimp connections

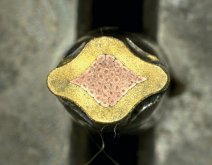

View lengthways through the crimp

A gas-tight crimp connection is the result of a defined crimping process. The wire strands in one or more conductors and a connector are joined into a largely homogeneous structure with no gaps. This results in a permanent, reliable connection that cannot be detached.

View crosswise through the crimp

In addition to the mechanical and electrical properties to be tested, a visual examination of the crimp area provides important information regarding the quality of the connection. To this end, micrographs or images are captured by means of computer tomography. The porosity, elongation at break, and the deformation of the individual wire strands is assessed in this way.

When crimping is performed correctly, it is largely protected from gases such as industrial atmospheres that contain sulfur dioxide and from oxygen, salt spray or other corrosive media. This prevents gases causing corrosion on the individual wire strands during the lifetime of the connection and any resulting deterioration in the electrical properties."

Reading this I get that the ferrule must be crimped sufficiently that it will not pull out under a predefined load (i.e. not loose). In addition it states that a gas tight seal is created by the crimping process that joins the wire and connector into a homogenous structure without voids.

I have a hard time imagining how a loose crimp could satisfy either of these conditions. I was already aware of the above requirements which is precisely why I stated what I did.