Just curious if someone goes with ground screws where do you get them from? I can't seem to find anyone that carries it. For my location at least need the 83" length for 3" pipe. Tried American Ground Screws and nobody answers. Talked to someone at Iron Ridge and they said there are issues getting ahold of them and to talk to whomever you will order the ground mount from (tried that and they didn't know where to get them either).I used a bobcat with an auger (attached), the auger happened to have an output shaft that fit inside the ground screws without much slop.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Finally, the start of my 25kw Ground Mount grid-tie system

- Thread starter live4soccer7

- Start date

MarkSolar

Solar Enthusiast

Usually it works best to get the ground screws from whoever supplies the rest of the mount system. Each company does something a little different with the interface between the ground screw and the vertical pipe. Unless you want to fabricate something yourself, it's probably easier to buy it all together. I bought a Sunmodo system, I got it from CEDgreentech. They've got places all over the country, there might be one near you. Mine was close enough that I got free shipping, saves a bunch because this stuff is really heavy.Just curious if someone goes with ground screws where do you get them from? I can't seem to find anyone that carries it. For my location at least need the 83" length for 3" pipe. Tried American Ground Screws and nobody answers. Talked to someone at Iron Ridge and they said there are issues getting ahold of them and to talk to whomever you will order the ground mount from (tried that and they didn't know where to get them either).

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,535

Wesbell Wiring: $420/1000' 2kv wiring (includes 1000' of black and red)

Will frequency watts ONLY be found on the hybrid controllers?

Copper wire? 10 awg?

It is for PV inverters, UL 1741 SA that I see the expression "frequency-watts"

Off-grid, you should be able to pick up older model Sunny Boy. They range from 700W to 10kW. Most but not all implement this feature.

A number of battery inverters (some hybrid with PV input, some not) implement frequency shift to command reduced power. Sunny Island of course; they pioneered it. Outback Skybox, some of the Schneider, several others I think. I don't have a good list of which do.

How much do you want to spend?

What sort of load do you want to start? (surge capabilities vary)

live4soccer7

Solar Enthusiast

- Joined

- Jun 15, 2020

- Messages

- 670

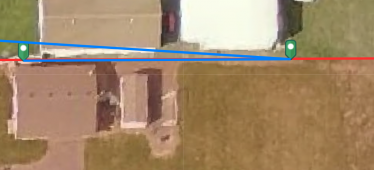

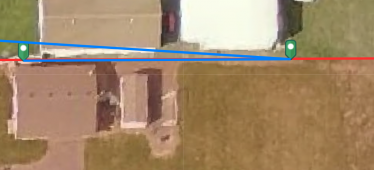

Sorry, I didn't see there were new posts until now. I have an open ditch in the area shown by the blue line because the utility company is replacing our underground power today. I have a few hours to figure out what I'm going to bury in this ditch, get it, and throw it in there before they close it up. I have to purchase it all tonight and throw it in before morning.

From green point to green point/marker. I was taking a screen shot and it wouldn't let me release the measure tool, so ignore the other blue line that's off to an angle.

1.5" pvc conduit for this:

I was thinking of throwing a 1/2" airline in the ground

RJ45 or Fiber

1.5" pvc conduit for this:

PV DC lines come to the inverter near the building on the west side

1.5" pcv:

120v back to the panels in case I need power out there

1.5"

for Shop power in the west portion of the some time in the future

That's probably close to 500' of conduit as the blue line mark is about 115' based on the measuring tool in the pic.

Can I combine any of these to reduce a conduit run? Probably the only thing that could be combined would be the 120vAC and the DC, but not sure if that is a "no no".

From green point to green point/marker. I was taking a screen shot and it wouldn't let me release the measure tool, so ignore the other blue line that's off to an angle.

1.5" pvc conduit for this:

I was thinking of throwing a 1/2" airline in the ground

RJ45 or Fiber

1.5" pvc conduit for this:

PV DC lines come to the inverter near the building on the west side

1.5" pcv:

120v back to the panels in case I need power out there

1.5"

for Shop power in the west portion of the some time in the future

That's probably close to 500' of conduit as the blue line mark is about 115' based on the measuring tool in the pic.

Can I combine any of these to reduce a conduit run? Probably the only thing that could be combined would be the 120vAC and the DC, but not sure if that is a "no no".

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,535

Bigger is better. I have a hard time fishing and pulling in conduit. How about 2"?

Even factory-cut PVC conduit needs to be reamed. One end of the conduit is spread out, not a problem. But the other end has a right angle which snags cable jacket, so ream it until it is chamfered heavily.

Even factory-cut PVC conduit needs to be reamed. One end of the conduit is spread out, not a problem. But the other end has a right angle which snags cable jacket, so ream it until it is chamfered heavily.

live4soccer7

Solar Enthusiast

- Joined

- Jun 15, 2020

- Messages

- 670

I did

1.5" for the DC lines

1.5" for power to the shop down (hopefully in a few years)

1.25" for RJ45 and an air line

3/4" for 120v out to the panels in case I want power out there

I ran a 1" irrigation line for water. The run was 120"

I spent way tooooooo much money on conduit today, it was painful. I'll post up a couple pics tomorrow. Some progress to show this isn't just an all talk thread.

1.5" for the DC lines

1.5" for power to the shop down (hopefully in a few years)

1.25" for RJ45 and an air line

3/4" for 120v out to the panels in case I want power out there

I ran a 1" irrigation line for water. The run was 120"

I spent way tooooooo much money on conduit today, it was painful. I'll post up a couple pics tomorrow. Some progress to show this isn't just an all talk thread.

MarkSolar

Solar Enthusiast

I assume you know there are separation requirements between different stuff in the same trench, especially for water pipes and electric.

Sanwizard

Solar Wizard

- Joined

- Feb 2, 2021

- Messages

- 2,714

10 gauge minimum. Check your inverter manual also.Perhaps someone will have an opinion or suggestion on this.

I can use 4mm2 (12 gauge) wire from the panels to the inverters. This is about a 300-350' run. I was thinking of stepping this up to 6mm2 (10 gauge) for two reasons.

1. I will get less of a voltage drop

2. It will allow me to run more current through it down the road if I have to upgrade/change panels in an array. Surely panels will only get more efficient and powerful.

live4soccer7

Solar Enthusiast

- Joined

- Jun 15, 2020

- Messages

- 670

Yeah, We are good to go. If I run into an issue with interference on the RJ45 then I can just do fiber. Otherwise, I do not think there is an issue with the different electricals types/voltages next to each other as long as they are in different conduits.I assume you know there are separation requirements between different stuff in the same trench, especially for water pipes and electric.

The workers didn't seem to care that I threw an irrigation line in there, so we will see what happens on that one. Worst case scenario is I will have to dig a shallow trench and run a new one closer to the surface, but I think it may be just fine. I had little time to adjust any planning. I literally had a 6-8 hours to figure out exactly what I wanted, buy it, install it, and bury partially. That put me in bed at 1230AM. A long day.

live4soccer7

Solar Enthusiast

- Joined

- Jun 15, 2020

- Messages

- 670

Yeah, that's what I'm going with now. I appreciate you chiming in and will keep a look out on anything specified in the inverter manual as well.10 gauge minimum. Check your inverter manual also.

MarkSolar

Solar Enthusiast

Not sure if this is a utility or code thing, but when I trenched in our utility electric they required me to separate my conduit carrying communications lines by 12" from the conduit I put in for them. I dug the trench deep enough I could put my conduit 12" on top of the one I put in for them. I didn't have anything else in the trench.Yeah, We are good to go. If I run into an issue with interference on the RJ45 then I can just do fiber. Otherwise, I do not think there is an issue with the different electricals types/voltages next to each other as long as they are in different conduits.

live4soccer7

Solar Enthusiast

- Joined

- Jun 15, 2020

- Messages

- 670

Thanks for the info. Yes, copper 10awg.Copper wire? 10 awg?

It is for PV inverters, UL 1741 SA that I see the expression "frequency-watts"

Off-grid, you should be able to pick up older model Sunny Boy. They range from 700W to 10kW. Most but not all implement this feature.

A number of battery inverters (some hybrid with PV input, some not) implement frequency shift to command reduced power. Sunny Island of course; they pioneered it. Outback Skybox, some of the Schneider, several others I think. I don't have a good list of which do.

How much do you want to spend?

What sort of load do you want to start? (surge capabilities vary)

live4soccer7

Solar Enthusiast

- Joined

- Jun 15, 2020

- Messages

- 670

I'd imagine it would be from emf (i believe) from the electrical lines. I could run into that issue and if I do then I'll certainly just run fiber, which is impervious to that.Not sure if this is a utility or code thing, but when I trenched in our utility electric they required me to separate my conduit carrying communications lines by 12" from the conduit I put in for them. I dug the trench deep enough I could put my conduit 12" on top of the one I put in for them. I didn't have anything else in the trench.

live4soccer7

Solar Enthusiast

- Joined

- Jun 15, 2020

- Messages

- 670

MurphyGuy

It just needs a bigger hammer

- Joined

- May 20, 2020

- Messages

- 4,129

I'd imagine it would be from emf (i believe) from the electrical lines. I could run into that issue and if I do then I'll certainly just run fiber, which is impervious to that.

My array feed is a direct burial 4ga 4 wire copper cable buried 48 inches down. I put 6 inches of dirt on top of it, then the 1/2 inch conduit for the ethernet cat5 line.

The below-grade distance to my array is about 80 feet. I have no issues with communications.

live4soccer7

Solar Enthusiast

- Joined

- Jun 15, 2020

- Messages

- 670

Yeah, I'm sure it will be fine. If not, I'll address any issues. My array will be roughly 200' from the inverter location shown by the stubs in the first photo. I'll probably build a "rack" there to hold the inverters instead of mounting them on the building.

Is mounting bifacial panels a big deal compared to single faced? My best deal is kind of looking like the local bifacial ones for $220 for the 450w + bifacial power. If it is going to be more of a headache or more expensive to mount them on the framing then I may look at a different panel.

Is the glass on the panels pretty darn tough? I was just thinking if I had to weedwack around the panels and the possibility of a small rock getting kicked up on the underside and breaking the glass. Should this be a concern or no?

Is mounting bifacial panels a big deal compared to single faced? My best deal is kind of looking like the local bifacial ones for $220 for the 450w + bifacial power. If it is going to be more of a headache or more expensive to mount them on the framing then I may look at a different panel.

Is the glass on the panels pretty darn tough? I was just thinking if I had to weedwack around the panels and the possibility of a small rock getting kicked up on the underside and breaking the glass. Should this be a concern or no?

MarkSolar

Solar Enthusiast

I was told when I looked into bifacials that grass is a poor reflector, so it doesn't buy you much. They recommended something light colored like concrete or gravel, and hopefully snow in winter.

live4soccer7

Solar Enthusiast

- Joined

- Jun 15, 2020

- Messages

- 670

I was thinking about gravel under the arrays anyways just to keep the area clean, but that kind dependent on funds after I finish up. At the least it would be dirt as I'd kill of the weeds a couple times through the non-winter months.

MurphyGuy

It just needs a bigger hammer

- Joined

- May 20, 2020

- Messages

- 4,129

The glass on the front of the panels is pretty tough.. surprisingly tough, and there are actual standards for it..Yeah, I'm sure it will be fine. If not, I'll address any issues. My array will be roughly 200' from the inverter location shown by the stubs in the first photo. I'll probably build a "rack" there to hold the inverters instead of mounting them on the building.

Is mounting bifacial panels a big deal compared to single faced? My best deal is kind of looking like the local bifacial ones for $220 for the 450w + bifacial power. If it is going to be more of a headache or more expensive to mount them on the framing then I may look at a different panel.

Is the glass on the panels pretty darn tough? I was just thinking if I had to weedwack around the panels and the possibility of a small rock getting kicked up on the underside and breaking the glass. Should this be a concern or no?

As for any glass on the bottom, I don't know.. I have no experience with bifacial panels.

wattmatters

Solar Wizard

When the services trench was dug for connecting our second dwelling, the 3-phase power line was the deepest, then the water main, then the data above that. Each has an identifying plastic ribbon draped on top of the conduit as a warning flag for any future diggers. The depth of each I forget but was to whatever our local code is. I think power is minimum 600mm for us. I think here data cable only needs to be 200mm down.I assume you know there are separation requirements between different stuff in the same trench, especially for water pipes and electric.

Similar threads

- Replies

- 5

- Views

- 397

- Replies

- 4

- Views

- 736