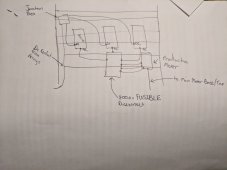

Since it will be a "meter tap" it won't run through my main breaker panels unless I were actually using all that power in the house/buildings. Even then, I have 3 separate breaker panels that feed from the meter. One that feeds the building the meter is on and two that feed the actual house. So.... From the meter tap, power has 3 ways to go in the means of me utilizing it. Of course, I won't use all that power so the rest just goes to the grid and will never see any of those panels.

They are 16 x 450W series, two per fronius inverter. That would be 14,400W PV per fronius 15k. They are bifacial, so I might get a little extra. Take into consideration losses etc... I'm sure I may be around 14kw PV on each inverter.

I won't quite be maxing everything out, but I'll be building everything out to be able to handle 200A+

For AC This means the transfer / shutoff switch, breakers, cable, junction boxes etc.... Do I need breakers, or would it be suggested, if I have a fusible switch?

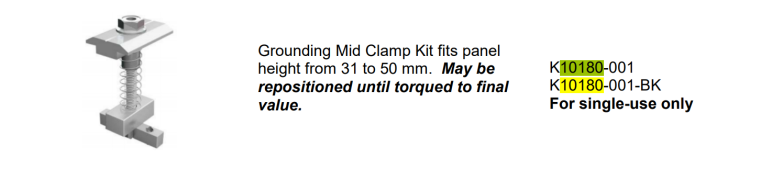

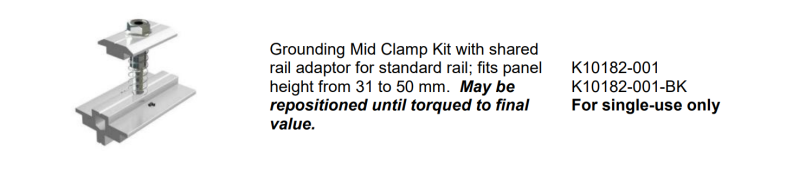

The PV side actually seems to be the easy side. Hook up the panels, hook them to the inverters and pretty much done.