I’m retiring my 2P busses/jumpers (32 cells) and going back to a diagonal #2 cables jumpers for 2 banks. The 2P jumpers I’ve been using 1” wide braid, 4 ply, fixture soldered and the contact area was embossed with 10,000 pounds of force( see photo). Despite this effort, it required regular re-torquing, especially initially. 6 months later, a monthly checks revealed a few still had an almost imperceptible movement when torquing. I don’t believe that this is acceptable because it should be a set and forget like the solid buss or lugs are. The Daly is acting up so going to two JK bms’s also instigated the decision. This got me to thinking about the guys that are running those laminated flexible buss bars with the orange middle(see picture). Those have a slot, somewhat wider than needed to clear a 6mm fastener. Add to that the small contact area of a welded stud, makes me wonder about the copper flowing with time. I’d like to get some feedback from users of those if they have checked the torque! I hope so!

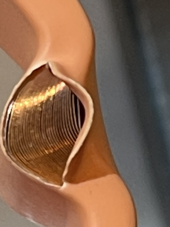

From what I’ve seen, I’m pretty much believe there’s only two ways to connect cells to not stress cell terminals though thousands of cycles. If you are not compressed, you can use a solid buss if you have a little gap between the cells. If you are compressed, the fixture shouldn’t be rigid, but measured spring tension to allow for expansion. I could imagine that the internal cell pressures could be enormous with high SOC & warmer temperatures with a non yielding fixture. The growth with cycles is surprising, approximately 3/16” for a 8 cell module(squeeze box) or .025” per center to center of terminals. (See Misaligned dots at full SOC and warm in photos) Because of this movement, a flexible jumpers would be desirable. The fixture spring pressure exerted on the cells is 550lbs (10psi). There’s a .040” silicone sheet between cells and the deformation of this with 10 psi is minimal. Four modules with 8 cells each, two modules for 48 volt battery (2 batteries)

From what I’ve seen, I’m pretty much believe there’s only two ways to connect cells to not stress cell terminals though thousands of cycles. If you are not compressed, you can use a solid buss if you have a little gap between the cells. If you are compressed, the fixture shouldn’t be rigid, but measured spring tension to allow for expansion. I could imagine that the internal cell pressures could be enormous with high SOC & warmer temperatures with a non yielding fixture. The growth with cycles is surprising, approximately 3/16” for a 8 cell module(squeeze box) or .025” per center to center of terminals. (See Misaligned dots at full SOC and warm in photos) Because of this movement, a flexible jumpers would be desirable. The fixture spring pressure exerted on the cells is 550lbs (10psi). There’s a .040” silicone sheet between cells and the deformation of this with 10 psi is minimal. Four modules with 8 cells each, two modules for 48 volt battery (2 batteries)

Attachments

-

371A7905-4DAF-4F57-812D-7F061FCFBA65.jpeg178 KB · Views: 54

371A7905-4DAF-4F57-812D-7F061FCFBA65.jpeg178 KB · Views: 54 -

A15AA1BA-4964-49AD-8756-5F9F8306167F.jpeg103.8 KB · Views: 52

A15AA1BA-4964-49AD-8756-5F9F8306167F.jpeg103.8 KB · Views: 52 -

CEB79A39-9ED2-401A-A07E-5E9E951FA191.jpeg131 KB · Views: 51

CEB79A39-9ED2-401A-A07E-5E9E951FA191.jpeg131 KB · Views: 51 -

BE46ECA9-F2D7-48BC-BEB3-949783D89D9F.jpeg307.4 KB · Views: 55

BE46ECA9-F2D7-48BC-BEB3-949783D89D9F.jpeg307.4 KB · Views: 55 -

F79AABBB-CD32-4E43-A973-A9083C52BAA5.png1.1 MB · Views: 56

F79AABBB-CD32-4E43-A973-A9083C52BAA5.png1.1 MB · Views: 56

Last edited: