svetz

Works in theory! Practice? That's something else

Flywheel Energy Storage

Flywheels with magnetic bearings are 97% efficient, have an 85% round trip efficiency, are not adversely affected by temperature, have high C-Rates, zero degradation (do not degrade over time based on DoD or C-Rate), unlimited cycling, are made of inert/benign materials, the SoC can be precisely determined via rotational speed, are sealed devices that need no/little maintenance, and have long lifespans.

So, why don’t we see more of these? You can find them on Alibaba, but at three times the $/kWh as LiFePO4. So, why are they so expensive?

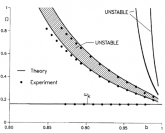

There’s the wobble issue: Left to its own, a spinning flywheel would slowly precess following the Earth's rotation. But that’s overcome by the magnetic bearings. There’s shock and vibration, the flywheel needs precision balancing; all these add up increasing the capital costs.

They’re also heavy… Amber Kinetics offers an 8kW/32 kWh flywheel that weighs in at 5 tons.

Back in 2013 the Velkess flywheel was supposed to be a drop-in replacement for 48V lead acid and cost around $1300/kWh. Their secret sauce to reducing costs was a flexible flywheel [video] that didn’t require precision and so would be cost effective.

So it seems like a great technology if someone can figure out how to reduce the manufacturing costs.

Flywheels with magnetic bearings are 97% efficient, have an 85% round trip efficiency, are not adversely affected by temperature, have high C-Rates, zero degradation (do not degrade over time based on DoD or C-Rate), unlimited cycling, are made of inert/benign materials, the SoC can be precisely determined via rotational speed, are sealed devices that need no/little maintenance, and have long lifespans.

So, why don’t we see more of these? You can find them on Alibaba, but at three times the $/kWh as LiFePO4. So, why are they so expensive?

There’s the wobble issue: Left to its own, a spinning flywheel would slowly precess following the Earth's rotation. But that’s overcome by the magnetic bearings. There’s shock and vibration, the flywheel needs precision balancing; all these add up increasing the capital costs.

They’re also heavy… Amber Kinetics offers an 8kW/32 kWh flywheel that weighs in at 5 tons.

Back in 2013 the Velkess flywheel was supposed to be a drop-in replacement for 48V lead acid and cost around $1300/kWh. Their secret sauce to reducing costs was a flexible flywheel [video] that didn’t require precision and so would be cost effective.

So it seems like a great technology if someone can figure out how to reduce the manufacturing costs.