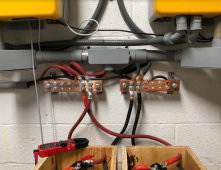

I'm running a home brew pair of LFP batteries with two BMSs. I've programmed the Sunny island 6048's to shut off at 42v. I'm not using the current shunt because I have two inverters, two batteries and a pair of morning star charge controllers. I would have to add another busbar into my system to get all the system current in/out thru one shunt. Despite the battery voltage being 53.3v and the morning stars keeping the battery pretty full all day, the SI shut down when it thought SoC was 15%.

So is there a way to make sunny island ignore it's own SOC estimate?

I understand there's a raspi program to communicate with the SI and you can set it up as a lithium battery. but what happens when the raspi fails? I'd like to keep this as simple as possible.

So is there a way to make sunny island ignore it's own SOC estimate?

I understand there's a raspi program to communicate with the SI and you can set it up as a lithium battery. but what happens when the raspi fails? I'd like to keep this as simple as possible.