stuntmanmike

New Member

- Joined

- Sep 12, 2021

- Messages

- 13

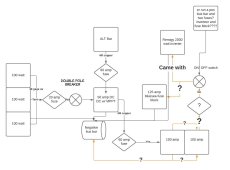

Hey guys Getting everything set up on my van solar build. I was just about to buy wire and ANL fuses, now my overtired head is second-guessing what I am doing. Installed everything thus far in 4awg from the local west marine, and freaked out that it was supposed to be 4/0. I have highlighted in pink what I am working on. I am basing this build off wills blueprint https://www.mobile-solarpower.com/simplified-400-watt-fewer-wires-and-alternator-charging.html which says 4awg.......

Help with the following

1. wire sizing between two 100 amp lithium in parallel. is it on discharge or total

2. is is better to come from POS to a shut off then to a POS bus bar with 2 fuses one to the 125 amp fuse block and the second to the inverter, or just size fuse correctly. At this time I am going to use the inverter cables that came with "doubled up 4awg"

2a or ditch the doubled up wires and go with (_____) size

3. ground the inverter lug 10awg to the back to the negative bus bar and ground the bus bar to the chassis "redundant grounding"?

thanks in advance, trying to do this once....

Help with the following

1. wire sizing between two 100 amp lithium in parallel. is it on discharge or total

2. is is better to come from POS to a shut off then to a POS bus bar with 2 fuses one to the 125 amp fuse block and the second to the inverter, or just size fuse correctly. At this time I am going to use the inverter cables that came with "doubled up 4awg"

2a or ditch the doubled up wires and go with (_____) size

3. ground the inverter lug 10awg to the back to the negative bus bar and ground the bus bar to the chassis "redundant grounding"?

thanks in advance, trying to do this once....