Sunnytheskoolie

New Member

- Joined

- Feb 12, 2021

- Messages

- 54

Hello there,

Would you have a moment to answer my questions, I'm a little confused with fuse sizing.

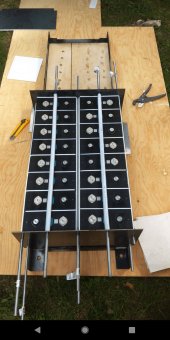

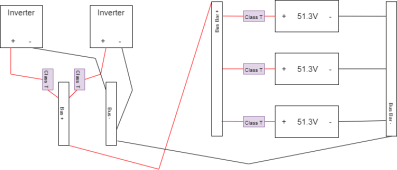

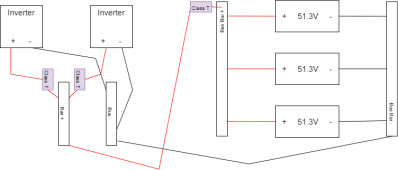

I have a 16s2p battery (51.2v 560ah) bank and am looking for a battery disconnect/fuse. I actually purchased the BlueSea M series but I didn't see that it was max rated for 48v and has a 300a rating. Do you know of a better manual disconnect that also has a fuse? I have been trying to find a Bussmann Tyco EV disconnect with a fuse but hard to come by.

My system doesn't have a fuse between my battery and my Lynx Distributor at the moment it only has the Contactor from my REC BMS and that Bluesea switch. Also, how would I calculate the fuse size to put in my Lynx Distributor? I have a 120v panel 100amp Square D panel(8 15 amp breakers and 2 20amp breakers), a 12v breaker box, and my MPPT hooked up to the Lynx Distributor and need fuses for each.

My solar array will be 9 400w panels 3s3p that will run through a Midnight solar Baby Box and a Victron Mppt.

Thanks for your help.

Derek

ps. my system is not connected I just have all the components.

Would you have a moment to answer my questions, I'm a little confused with fuse sizing.

I have a 16s2p battery (51.2v 560ah) bank and am looking for a battery disconnect/fuse. I actually purchased the BlueSea M series but I didn't see that it was max rated for 48v and has a 300a rating. Do you know of a better manual disconnect that also has a fuse? I have been trying to find a Bussmann Tyco EV disconnect with a fuse but hard to come by.

My system doesn't have a fuse between my battery and my Lynx Distributor at the moment it only has the Contactor from my REC BMS and that Bluesea switch. Also, how would I calculate the fuse size to put in my Lynx Distributor? I have a 120v panel 100amp Square D panel(8 15 amp breakers and 2 20amp breakers), a 12v breaker box, and my MPPT hooked up to the Lynx Distributor and need fuses for each.

My solar array will be 9 400w panels 3s3p that will run through a Midnight solar Baby Box and a Victron Mppt.

Thanks for your help.

Derek

ps. my system is not connected I just have all the components.