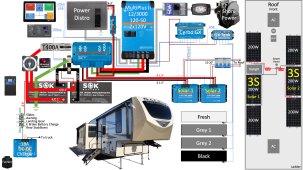

I'm installing a full system (400Ah LiFePO4, Victron Multiplus, SCC, 800w solar, etc.) and I've run into a spot I could use some suggestion on.

The factory load center is a WFCO 8955. I'm of course removing the stock converter, but I'll still be using the built in AC and DC panels. The DC panel was wired from the factory with only 8AWG line coming in, protected by a 30A breaker. That seems unnecessarily limiting to me, so I'm thinking I should size up the wiring and the breaker. The DC panel is labelled as 150A total.

The ABYC wire chart tells me that at 20' I should be good for 40A, so would folks here recommend just bumping up to a 40A breaker on my new system, or maybe go to 6AWG and use a 50A or 60A breaker?

Unfortunately I can't really say what my max combined DC load will be at this time. I've not tripped the 30A breaker, but the trailer was only used once prior to me ripping it apart, and I do plan to add additional DC loads in the future (LTE router, misc other small devices). I figured since I'm running other wiring and have to at a minimum re-route the factory wiring I may as well future-proof it.

Thanks for any input

The factory load center is a WFCO 8955. I'm of course removing the stock converter, but I'll still be using the built in AC and DC panels. The DC panel was wired from the factory with only 8AWG line coming in, protected by a 30A breaker. That seems unnecessarily limiting to me, so I'm thinking I should size up the wiring and the breaker. The DC panel is labelled as 150A total.

The ABYC wire chart tells me that at 20' I should be good for 40A, so would folks here recommend just bumping up to a 40A breaker on my new system, or maybe go to 6AWG and use a 50A or 60A breaker?

Unfortunately I can't really say what my max combined DC load will be at this time. I've not tripped the 30A breaker, but the trailer was only used once prior to me ripping it apart, and I do plan to add additional DC loads in the future (LTE router, misc other small devices). I figured since I'm running other wiring and have to at a minimum re-route the factory wiring I may as well future-proof it.

Thanks for any input