WarpedJester

New Member

- Joined

- Jul 10, 2020

- Messages

- 43

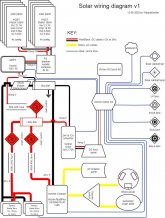

I am getting ready to install a big Victron system in my RV and am looking for some help/input on questions I have about the setup and programming of all the victron parts.. i am basing my build off off a layout i found on the Victron site https://www.victronenergy.com/upload/documents/MultiPlus-system-example-5KW-24V-230V-AC.pdf) but i wanted to get some input on some of the elements in that layout as well as the modification i have made in my layout (below).

The first thing is that on the Victron PDF they show all of there gear being powered directly off the 24V rail. Am i reading that right?

the next thing is that i have been trying to read up on prep work for hardware and i am still not confident that i have a clear picture regarding order of process or prepping each part. namely, if i should be plugging each item in on its own and stepping through system config and update before installing or what.

Bottom line, i have already invested over $10,000 into all the gear and i am now getting cold feet as i get ready to start touching wires to systems so i am hoping people here can help me out or help me find some solid walk throughs/how-to's.

Any input would be greatly appreciated. i am kinda freaking out a little right now.

The first thing is that on the Victron PDF they show all of there gear being powered directly off the 24V rail. Am i reading that right?

the next thing is that i have been trying to read up on prep work for hardware and i am still not confident that i have a clear picture regarding order of process or prepping each part. namely, if i should be plugging each item in on its own and stepping through system config and update before installing or what.

Bottom line, i have already invested over $10,000 into all the gear and i am now getting cold feet as i get ready to start touching wires to systems so i am hoping people here can help me out or help me find some solid walk throughs/how-to's.

Any input would be greatly appreciated. i am kinda freaking out a little right now.