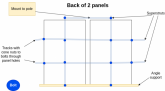

Made some progress. I got the smaller profile

14 gauge Superstruts. Wanted the big ones, but because these will ultimately be suspended in the air, I chose less weight for now. Can always upgrade later.

Started with 3/8" hex bolts. But, discovered that they won't fit through the holes in the 320W panel. Even if I drilled new holes, the washers were too wide as well. So, got 1/4" hex bolts and swapped the Superstrut 3/8" cone nuts for

the 1/4". Then discovered that with the smaller profile Superstrut rail, the 1" long bolt is too long. In the end, the 3/4" x 1/4" hex bolts work. Now I can get the panels on the Superstruts. Note that the 1" long bolts would work fine with the larger profile 12 gauge Superstruts. You can probably even go longer.

I have not tried to add anything such as lock washers or an extra bolt at the end. I'm not sure they'll be critical as this is primarily to get the panels on the rack. The stability and security will come from the side clamping where I'll have more freedom to add things to longer bolts. I'll probably use foil tape to keep the smaller bolts from coming loose. But, I've find that stuff to be insanely durable outdoors. I won't say how I know, because people shake their head when I explain how it has held up for over 10 years in a heavy water location.

I'm saving the 3/8" bolts for clamping the sides of the panels. This is where most of the security and stability should come from.

Honestly, I think there is a high probability I'll upgrade to the bigger struts. I just don't want to add the weight until I'm sure how I'll mount this. For now, this buys me time to work that out and enough stability to leave it outdoors while I complete this project.