Zero_PD

New Member

Hi all,

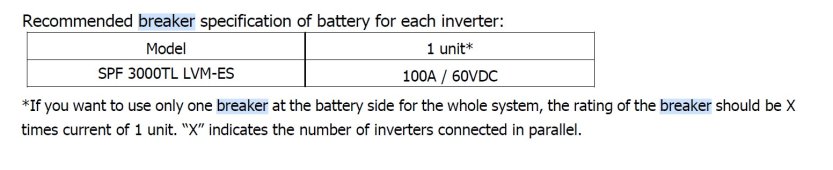

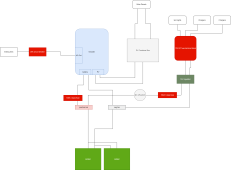

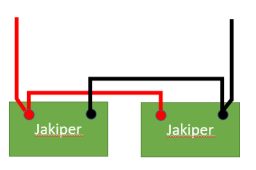

I'm working on the system diagram for my first off-grid system and I'm having a tough time answering a question about circuit breakers. I've read through the manual for the Jakiper 48V batteries and the Growatt SPF 3000 but I fear my electrical knowledge is a little rusty. The diagram is below - all breakers/fuses are in red. My main questions are about the Growatt.

Thanks for your help!!

I'm working on the system diagram for my first off-grid system and I'm having a tough time answering a question about circuit breakers. I've read through the manual for the Jakiper 48V batteries and the Growatt SPF 3000 but I fear my electrical knowledge is a little rusty. The diagram is below - all breakers/fuses are in red. My main questions are about the Growatt.

- Should I have a circuit breaker in between the Growatt and my battery bank? The manual says "it’s requested to install a separate DC over-current protector or disconnect device between battery and inverter". Does 100A look right? And - pardon the rookie question - what is this protecting against? A short which would try to pull too much current from the Growatt?

- Should I have a circuit breaker between the Growatt and my AC Load? Since the growatt is 3000w at 120V I assume it can only source 25A, which is why I tossed a 25A circuit breaker in the diagram. Would love to know if I am off base here.

Thanks for your help!!