tjoiner1986

New Member

Just looking for a 2nd opinion here.

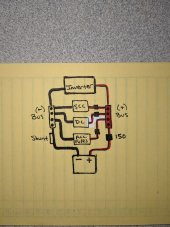

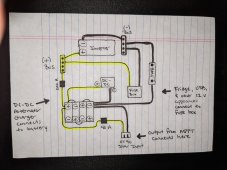

200 watts worth of 12V panels

Victron SmartSolar 100/30 charge controller

Orion 12/12-30 isolated DC charger for alternator charging

BMV-712 with shunt for battery monitoring and to remotely disconnect the DC charger during low temps

1200-watt Giandel inverter (may upgrade to a Multiplus down the road if I decide to add shore power)

200 watts worth of 12V panels

Victron SmartSolar 100/30 charge controller

Orion 12/12-30 isolated DC charger for alternator charging

BMV-712 with shunt for battery monitoring and to remotely disconnect the DC charger during low temps

1200-watt Giandel inverter (may upgrade to a Multiplus down the road if I decide to add shore power)

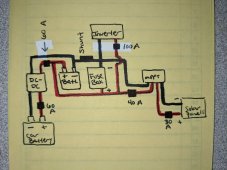

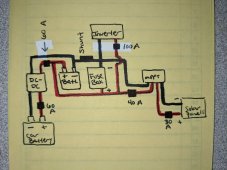

- 1200W inverter divided by 12V equals 100A breaker, correct?

- 60A breakers on the charger because that's what the manual calls for.

- 6 AWG going TO the charger because that's what the manual calls for.

- Since the charger only outputs no more than 30 amps, I may do 8 AWG (rated 40 A) and a 40 A breaker coming FROM the charger.

- Per the Victron manual, the BMV shunt goes directly to the battery (-) with the load attached to the other end.

- 10 AWG between panels and charge controller.

- 8 AWG between the charge controller and the battery.

- 4 AWG between the inverter, shunt, batter, everything else.

Last edited: