Have 3 400w 48v panels. Want to charge 4 LI Batteries 12 volt in series-parallel to create a 24v system. Looks like if I go with panels in series the controllers jump to over $800 - is the best option to put panels in parallel to save money on the controller?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help with Charge Controller Sizing

- Thread starter JBringolf

- Start date

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

In general, Higher current is more expensive than higher voltage on SCCs. Could you give us the specs on your panels? Are they some of the new panels that have really high voltages?

Voc?

Isc?

Vmp?

ImP?

Voc Temp Coefficient?

Voc?

Isc?

Vmp?

ImP?

Voc Temp Coefficient?

Q CELLS Q.PEAK DUO L-G7.2 400 400W Solar Panel - Low Price

Low wholesale price on the latest Q CELLS Q.PEAK DUO 400 solar panel w/ 144 half-cut cells. Expert advice & complete systems. Authorized Q CELLS supplier.

Q CELLS Model Number Q.PEAK DUO L-G7.2 400

STC Rating 400.0 Watts

PTC Rating 372.7

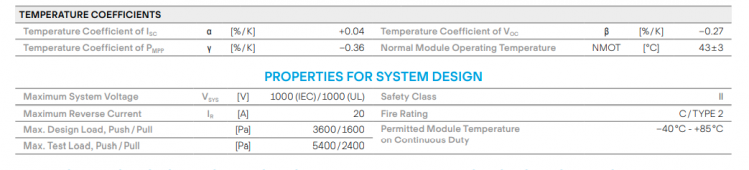

Open Circuit Voltage (Voc) 48.96 Volts

Short Circuit Current (Isc) 10.19 Amps

Frame Color Silver

Origin USA

Power Tolerance -0 / +5W

Module Efficiency ≥19.9%

MisterSandals

Participation Medalist

Open Circuit Voltage (Voc) 48.96 Volts

Never!!!Voc 48.96 -> 150V controller should be OK

It would only take a couple degrees below 25C (77F) for the panel voltage to exceed the 150V limit.

If you don't know better, you should not be giving bad advice repeatedly.

No, three of these panels in series will not be OK with a 150V charge controller unless the solar panels never get below 25ºC. And even then, 147V is awfully close to 150V.Voc 48.96 -> 150V controller should be OK.

So - for a starter backup system - to keep costs low. Go with a parallel configuration, which would require a controller for example: 100v and 40 amps ?

EPEVER 40 Amp MPPT Solar Charge Controller 150V PV Input Negative Ground

by SolarEpic

Learn more: https://www.amazon.com/dp/B00YCI48F4/ref=cm_sw_em_r_mt_dp_FPE25GVGXRMW9V9N22QA?_encoding=UTF8&psc=1

EPEVER 40 Amp MPPT Solar Charge Controller 150V PV Input Negative Ground

by SolarEpic

Learn more: https://www.amazon.com/dp/B00YCI48F4/ref=cm_sw_em_r_mt_dp_FPE25GVGXRMW9V9N22QA?_encoding=UTF8&psc=1

Last edited:

You are right. You have a risk to damage MOSFETs inside your charger in some rare conditions if high insolation, low temperature and no load happened simultaneously. But it does not create a fire hazard just breaks your controller. So you have choice to loose a cheap controller if you unlucky or pay $800+ and sleep well.No, three of these panels in series will not be OK with a 150V charge controller unless the solar panels never get below 25ºC. And even then, 147V is awfully close to 150V.

MisterSandals

Participation Medalist

The problem is that your panels have a voltage, when the temp drops, of over 50Voc and a charge controller of 100V max won't handle 2 in series. A 150V max won't handle 3 in series. Its just a weird consequence of panels with that particular voltage.100v and 40 amps

Lets do some math on your panels and how that works with your batteries (and 24V).

400W x 3 = 1200W

1200W / 25.6 (nominal voltage) = 46.8 amps charging maximum

If you put all 3 panels in parallel, you'll have to wire and fuse each panel for 30 amps. Its a bit of a hassle but doable. Long runs from panels to SCC will make that increasingly difficult and spendy.

Not sure if that is better than getting an SCC that will handle all 3 panels in series (very easy to wire), but expensive. Victron 250/50 would be pretty deluxe.

Maybe someone has a better recommendation for a charge controller (i am a Victron fanboy so consider that). There are a number of other SCC's that accept 200V (EPEver? but i have no experience with them).

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

Series:

Q CELLS Q.PEAK DUO L-G7.2 400 400W Solar Panel - Low Price

Low wholesale price on the latest Q CELLS Q.PEAK DUO 400 solar panel w/ 144 half-cut cells. Expert advice & complete systems. Authorized Q CELLS supplier.www.solarelectricsupply.com

Q CELLS Model Number Q.PEAK DUO L-G7.2 400

STC Rating 400.0 Watts

PTC Rating 372.7

Open Circuit Voltage (Voc) 48.96 Volts

Short Circuit Current (Isc) 10.19 Amps

Frame Color Silver

Origin USA

Power Tolerance -0 / +5W

Module Efficiency ≥19.9%

Without compensating for voltage rise in low temp, your Voc for series is 48.96 * 3 = 146.88.

Without knowing the lowest temp you will see, I will just assume -10F (-23C) That means your % change is 25-(-23)*.27=13% That means your Max voltage is 146.89 * 1.13=166V

Short Circuit Current is 10.19A. However, for looking up wire size you have to multiply by 1.55 (This is the NEC Safety Margin) so the wire has to be ratted for 15.7A (12AWG)

You do not have to put breakers on the panels, but a disconnect is required/suggested.

Parallel:

Without compensating for temp, the VOC is 48.96. Compensating for -10F we get 48.96*1.13=55.32V

With 3 panels in parallel, there must be breakers at the point the panels tie together....this typically means a combiner box.

Short Circuit Current is 10.19x3=30.57A with the NEC Safety multiplier it is 30.57*1/55=47.38A so the wire from the combiner box to the charge controller must be sized for 47.38V. (6AWG)

So.... if your wires are all short, you total system cost may be lower in parallel, but it could turn out to be cheaper in series if you have a long run from the panels to the SCC.

Excellent - Thank you. Leaning toward: Victron 250/60 and stay serial.Series:

Without compensating for voltage rise in low temp, your Voc for series is 48.96 * 3 = 146.88.

Without knowing the lowest temp you will see, I will just assume -10F (-23C) That means your % change is 25-(-23)*.27=13% That means your Max voltage is 146.89 * 1.13=166V

Short Circuit Current is 10.19A. However, for looking up wire size you have to multiply by 1.55 (This is the NEC Safety Margin) so the wire has to be ratted for 15.7A (12AWG)

You do not have to put breakers on the panels, but a disconnect is required/suggested.

Parallel:

Without compensating for temp, the VOC is 48.96. Compensating for -10F we get 48.96*1.13=55.32V

With 3 panels in parallel, there must be breakers at the point the panels tie together....this typically means a combiner box.

Short Circuit Current is 10.19x3=30.57A with the NEC Safety multiplier it is 30.57*1/55=47.38A so the wire from the combiner box to the charge controller must be sized for 47.38V. (6AWG)

So.... if your wires are all short, you total system cost may be lower in parallel, but it could turn out to be cheaper in series if you have a long run from the panels to the SCC.

MisterSandals

Participation Medalist

This would be 1600W so max charging amps would beBut if you have four, put them in 2S2P and you could use the 150/35 ($325).

1600W / 25.6V = 62.5A

But you could put 2 panels facing east-ish and 2 panels west-ish to lengthen your solar charging hours (poor mans tracking is more panels!)

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

Charge controllers are rated by input voltage and output current. With 4 panels the output current is 1600/24=67A on an empty battery and 1600/28.8V=55.6A. In the real world you won't get the full power so a 60A controller is probably about right for 4 panelsVictron does have a 250/60 ($640) which would allow up to 4 of those panels in series. But if you have four, put them in 2S2P and you could use the 150/35 ($325).

For 3 Panels, you would see 50A for an empty battery and 41.6A on a full battery.

In either the 4 panel or 3 panel case, a 150/35 would waste a lot of the capability of the panels no mater how the panels are wired.

The 'exception' to this is @MisterSandals suggestion of Poor mans tracking. With 2 west-ish and 2-eastish, you will never get full production anyway so a 150/35 might be OK.

BTW: If you do the poor mans tracking. Make sure to put in blocking diodes.

Yeah, my suggestions were too low on the amps side. I just plugged the panels into Victron's SCC spreadsheet. The 250/70 ($736) would be better for 4S and the 150/70 ($589) would be way better for 2S2P.

Even at 70A you could, in theory, lose a few potential charging amps in really cold weather. But given the rare conditions that would get you that many amps, it's not worth going higher than 70A.

Even at 70A you could, in theory, lose a few potential charging amps in really cold weather. But given the rare conditions that would get you that many amps, it's not worth going higher than 70A.

Right. I got carried away with the idea of considering 4. With 3 in series the 250/60 is fine. And it would still work with 4 in series. But you would lose some potential charging amps though at that point.Only have 3 panels

Similar threads

- Replies

- 86

- Views

- 2K