Hi,

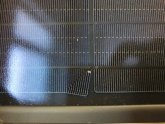

I have ordered 4 panels each are 60cells 1.5*1 meters. Together with around 50Kg of batteries and MPPT chargers. Unfortunately, they have put the heavy box on top of the middle of the solar panels and they have travelled over many countries via sea and road. So that 50Kg have been bouncing and flexing the panels all the way to me. Check attached picture to see how I got them. The panels package had clearly couple of "Do not stack" on them.

After further inspection, I noticed many and one broken cell module. I contacted seller and they offered to replace the panel with broken module and also the one on top ( under the heavy box). I told them all of them have signs and scratches as evidence that all of them got beaten up. I told them that I cannot see the cracks in other module as they are invisible, but they reduce the panel power and longevity. They said no scratches does not effect the functionality. I explained over and over it is not the scratches that I am concerned about, it is the module and cracks in them. I even sent them video about invisible damage caused by heavy pressure point.

What can I do to prove the damage to them? Is it possible to check each module individually?

Here is album of all the scratches:

https://photos.app.goo.gl/irQfC5ZQf3rRZsuG7

The video I sent them:

I have ordered 4 panels each are 60cells 1.5*1 meters. Together with around 50Kg of batteries and MPPT chargers. Unfortunately, they have put the heavy box on top of the middle of the solar panels and they have travelled over many countries via sea and road. So that 50Kg have been bouncing and flexing the panels all the way to me. Check attached picture to see how I got them. The panels package had clearly couple of "Do not stack" on them.

After further inspection, I noticed many and one broken cell module. I contacted seller and they offered to replace the panel with broken module and also the one on top ( under the heavy box). I told them all of them have signs and scratches as evidence that all of them got beaten up. I told them that I cannot see the cracks in other module as they are invisible, but they reduce the panel power and longevity. They said no scratches does not effect the functionality. I explained over and over it is not the scratches that I am concerned about, it is the module and cracks in them. I even sent them video about invisible damage caused by heavy pressure point.

What can I do to prove the damage to them? Is it possible to check each module individually?

Here is album of all the scratches:

https://photos.app.goo.gl/irQfC5ZQf3rRZsuG7

The video I sent them: