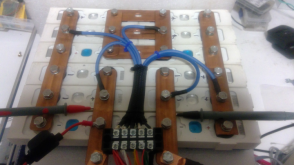

Are there any general recommendations on how to clean up wire clutter with a centralized BMS? My layout currently looks like a pile of spaghetti and need to do something to clean it up. Also wondering what would be good if wanted to have wiring for BMS that crosses over/touches the opposite battery post since would make the layout simpler or if I should just avoid doing that. This is for 48V system so lots of wires.

How to clean up BMS wire clutter?

- Thread starter rhino

- Start date