I don’t actually understand this whole thread for three tab shingles after having done a reroof last year and DIY install for the first time this summer. Maybe for other roofing materials front loading the work is a good idea.

For a reroof I buy that moving plumbing ducts and HVAC vents at the time of roofing makes a ton of sense. Those would be painful to patch and are also pretty big.

Bias disclaimer: I have easy attic access to below the rafters to visually verify that rack anchors went in with correct alignment and no bursting

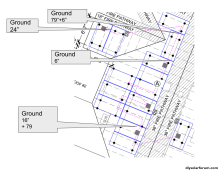

Below blindly installing brackets means just putting them up there with only a draft plan of where the panels will go. At least have a layout done with some roughly representative panels, understand different panel geometries, and understand setbacks from the roof ridge and other places.

I would say ironridge is probably a better rail for blindly installing brackets as you suggest, since it has longer cantilever to compensate for being imprecise with rail placement.

The main advantage I can think of for doing it at roofing time is that it is slightly easier to find rafters if the roofer marks them as the roof is built up. But you can also find rafters using feeler holes and then use standard size foot flashing to cover it. You have a foot of horizontal spacing with the flashing to cover up your feelers. If you are using compact foot flashing then you have to be much more precise with feelers, so maybe this is something good to delegate to a contractor with more experience.

Maybe you can avoid pulling nails that pulling flashing after the fact would require.

A big disadvantage of blindly installing brackets without knowing panels nor layout is that it increases the likelihood you will not mount the panel clamps on the approved area.

Another disadvantage is whether the roofer knows the rack hardware.

There are videos with all of the different flashes roof junction boxes in one. Some use big flashings which is good for wiggle room but bad for cutting shingles and pulling nails.