Johnny Doe

New Member

- Joined

- Nov 3, 2022

- Messages

- 1

Hi,

I have recently bought a Victron Phoenix 12/1200 inverter and want help finding correct size for a external fuse on the positive wire, there is already a internal 200A MIDI 32V fuse inside the inverter.

I'm planning on using a AWG2 (~35mm2) wire to my Victron Phoenix 12/1200 inverter which is recommended in the manual if wire length is longer than 1,5 meters. My wire will be much shorter, but I want to minimize power losses.

Datasheet

Manual

Inverter specifications:

Voltage = 12V

Continuous power = 1000W

Peak power = 2200W

Max efficiency = 91%

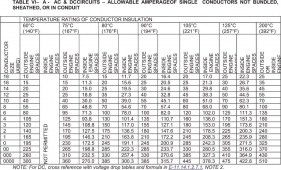

1) What is the max current a 2 AWG wire can handle? I have seen everything from 125-200A on the internet.

2) Should I size my fuse for cont. power or peak power?

(1000 / 12) * 0,91 = 75,83A

75,83 * 1,25 = 94,78A

(2200 / 12) * 0,91 = 166,83A

166,83 * 1,25 = 208,54A

3) What kind of fuse should I use? Mega, ANL or T fuse? Why?

I have recently bought a Victron Phoenix 12/1200 inverter and want help finding correct size for a external fuse on the positive wire, there is already a internal 200A MIDI 32V fuse inside the inverter.

I'm planning on using a AWG2 (~35mm2) wire to my Victron Phoenix 12/1200 inverter which is recommended in the manual if wire length is longer than 1,5 meters. My wire will be much shorter, but I want to minimize power losses.

Datasheet

Manual

Inverter specifications:

Voltage = 12V

Continuous power = 1000W

Peak power = 2200W

Max efficiency = 91%

1) What is the max current a 2 AWG wire can handle? I have seen everything from 125-200A on the internet.

2) Should I size my fuse for cont. power or peak power?

(1000 / 12) * 0,91 = 75,83A

75,83 * 1,25 = 94,78A

(2200 / 12) * 0,91 = 166,83A

166,83 * 1,25 = 208,54A

3) What kind of fuse should I use? Mega, ANL or T fuse? Why?