Spudtoo

New Member

- Joined

- Aug 28, 2022

- Messages

- 4

Hello Everyone,

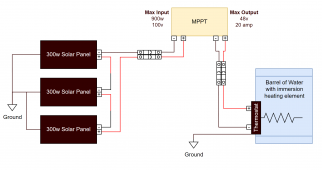

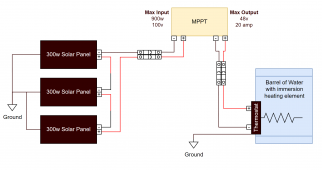

New to this forum so be gentle. I've got a very early concept idea for directly heating a concrete block using second hand PV panels.

The basic idea being a DC heating element embedded in a concrete block (heat storage) warms during the day and emits heat gradually thereby smoothing out the PV output. I'm thinking a max 2kw, the same as my wife uses on a fan heater which cost us a bomb to power last winter.

Any feedback welcome on this idea, particularly any ideas how the PV panels need to be connected to the "heater element" and what sort of "heater element" I could use.

Some requirements:

Updated Diagram below:

New to this forum so be gentle. I've got a very early concept idea for directly heating a concrete block using second hand PV panels.

The basic idea being a DC heating element embedded in a concrete block (heat storage) warms during the day and emits heat gradually thereby smoothing out the PV output. I'm thinking a max 2kw, the same as my wife uses on a fan heater which cost us a bomb to power last winter.

Any feedback welcome on this idea, particularly any ideas how the PV panels need to be connected to the "heater element" and what sort of "heater element" I could use.

Some requirements:

- I don't want to introduce batteries

- I don't want to use an inverter

- I intend to use second-hand PV panels

- This is a "top-up" heating solution - the house has gas powered central heating

Updated Diagram below:

Last edited: