RCinFLA

Solar Wizard

- Joined

- Jun 21, 2020

- Messages

- 3,559

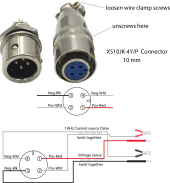

If it is really 0.36 milliohms near 25 degs C that is pretty poor for 280AH cell. If you have a current shunt in 0.1 to 0.5 milliohm range you can check your meter accuracy. (shunt mV divided by current rating = shunt resistance, 75mV/500 amp = 0.150 milliohms) Always check on battery terminals directly, not on top of bus bars. Low temp increases Rs (see attached pict) Full charge is a bit higher Rs. 50-80% SOC gives best Rs.

Most of degrading side chemical reactions that increase cell Rs also ties up lithium reducing capacity.

View attachment 56779

Most of degrading side chemical reactions that increase cell Rs also ties up lithium reducing capacity.

View attachment 56779