It's a 1/2" resin coated plywood.

www.penn-elcom.com

It's really good to work with and has a nice looking finish. I thought it was a little pricey when I bought it back in march, but I think it was cheaper than what standard plywood is running now. I had to drive to houston to get it, couldn't find any in austin area.

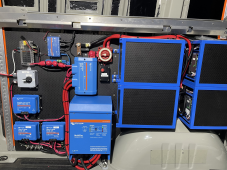

Everything except the batteries and invertor are just screwed into the plywood. For the batteries, I fabricated a steel support structure behind the plywood and the inverter bracket uses some rivnuts into the van wall frame. The invertor probably would have been fine just through bolted to the plywood, but the batteries are about 250lbs total and needed structural support.