I bought the 4kw WZRELB. $460 on ebay shipped to me.

1) I realized my victron multiplus compact 24/2000 is a low frequency unit. Even though it is rated at 2kw and 4kw surge. My opinion is that Victron underrated it. Neither unit will start my air conditioner. I started it from home power, then turned on the WZRELB. I now have 2 transfer switches in series. The second thinks my WZRELB is a generator so it waits many seconds before it switches it in, so I am sure it was up to 120v. As soon as the transfer switched in the WZRELB, the AC died. The WZRELB showed 70 volts on its AC meter. I have not tried that test with the Victron. I might. This is annoying because the locked amps of the 2 motors in my AC should require 7kw and the WZRELB should surge to 8kw, so you'd think that it is very close to starting the AC. I expected it to be able to take over a running AC.

I am torn up about this. On the one hand, I feel like getting a 4kw low frequency unit. They are about $650. On the other hand, why not get a $300 soft start thing for the AC? This would reduce the surge amps needed and allow faster blow fuses/breakers in the wiring, which would feel safer. The bigger unit would be a lot heavier and that would be a problem in my water bay of the RV where I am putting the batteries and inverter.

I compared my Victron to the WZRELB at starting my small table saw. Both spun it up slower than home power. It seems like the Victron started it a bit faster.

I turned on my water heater which should be 1440 watts, and a 1500watt space heater. The WZRELB showed 118 volts and powered those for several minutes before I got bored. I measured 150amps from the 24v battery which agrees with 3kw of power plus some waste.

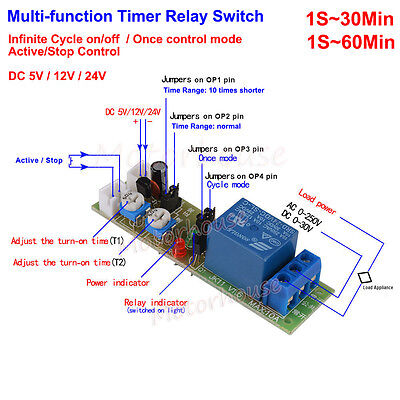

2) I had to pick out some hot glue that holds the power switch in the WZRELB and was then able to push it out the front. I had no trouble soldering in series some wires. However, others have reported that the elctrodacus SBMS0 opto isolators (relays) fail to provide enough current to power them properly. Dacien says that the LED volt meter on the inverter is wired in series with the switch and recommends cutting the wire to it. Because I am not sure I will keep the WZRELB, I bought a 1amp relay that is used to trip the WZRELB. I measured a fluctuating 80mAmps through the switch, so I suspect it peaks over 150mAmps which is the SBMS0' opto isolator's max.

(Note: Dacien's instructions say to wire the switch in parallel, which seems idiotic to me. If the switch is turned on, then the SBMS0 cannot turn the unit off. So a parallel switch is useless, but could be mistakenly put on and kill the batteries. If in series, all makes sense. His argument was that it was easier to solder 2 leads onto the switch. So what, do it right.)

I made a little board that has screw connectors for all the signal wires. I added the relay to it. This board is basically an easy connector spot for: 2 remote switches (for the DC/DC converter and the inverter), 4 signals for the 2 loads and 1 charger and PV from the SBMS0, and 4 signals going to same loads.

The SBMS0 is very annoying in that the EXT IO3/4 are little push in connectors, but EXT IO5/6 require you to solder in a connector to the main board (included) but it uses a ribbon cable. Dacien needs to clean this up and make all outputs available via the same port. Unless I put 3 more relays on my little circuit board, I need all 4 EXT IOs because all 4 charge/loads are different electrical characteristics.

3) I measured 1amp at idle for the inverter (24watts), which seems reasonable to me.

4) The "smart" fan is not the smartest. It is either on or off. When on, it is somewhat loud. It was going on and off with a period of many seconds. I mounted it in the water bay, which is below the main floor of the RV, so I think it will be reasonably quiet there. The Victron had essentially the same sized fans and thus was equally noisy when under load. I don't know the efficiency comparison between the two, or between an LF vs HF. So I assume that a LF unit, with the bigger case could have a bigger fan that could run slower and if the LF unit is more efficient, then it does not have to dissipate as much heat.

In summary, I think I will stick with the WXRELB. I don't relish the idea of taking a chance on a bigger unit. The struggle of fitting it is not worth it and the odds of making a mistake with respect to the remote power switch capability is not worth it.

I could have kept the Victron, but I suspect I will be able to sell it for at least what I paid for the WZRELB. I feel like the WZRELB should handle more resistive loads.