While I'm waiting on the slow boat, I have time to plan ahead on my installation. I've purchased 16 200 ah cells that will be configured in a 2P8S 24 volt block with a JBD 100 amp BMS. My application is a 1500 watt inverter that rarely goes above 60 amps surge when one of the refrigerator or freezer compressors starts up. The other 99% of the time it loafs along at 15 - 25 amps load. I'll be using a fixed voltage charger set at a voltage (TBD) to charge and maintain (float) around 95% cell capacity. This charger has very good voltage regulation and its maximum current delivery is 20 amps. There is a small parasitic load of around 500 ma all the time for the standby function of the inverter. This is basically a UPS for my essentials and a quiet alternative to running the generator at night if there's a power outage. Historically it only gets used a few times a year.

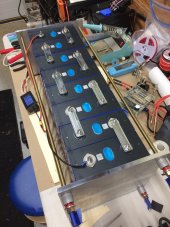

Sooo... since I'm going to have a relatively low charge and discharge rating in relation to the capacity, do I really need to go to the trouble of binding and compressing the cells? I'll be removing the AGM batteries from the rack and the entire block of cells will fit on the top shelf.

Sooo... since I'm going to have a relatively low charge and discharge rating in relation to the capacity, do I really need to go to the trouble of binding and compressing the cells? I'll be removing the AGM batteries from the rack and the entire block of cells will fit on the top shelf.