Jamie.sanders

New Member

- Joined

- Dec 1, 2019

- Messages

- 159

Attachments

Last edited:

Well I am leaning and building, I think this is correct except for things I don't know, where all to put fuse's and circuit breakers etc.

I even bought a Solar book, trying to learn. any advise or suggestions would be appreciated. View attachment 74811any advise or assistance would be greatly appreciated.

OK, thanks, I originally drew it with 3 BMS's, but wasn't sure I needed 3 if I stayed in series. if 3 is better thats what I want.Good basic start. Devil is in the details.

The way you have the panels sketched, it looks like they're in parallel, but you do indicate 2S3P. You will need a fuse or breaker on EACH string, i.e., each 2S gets a fuse/breaker before you parallel them. Given your 240 ft run, you should assess the possibility of using 3S2P as I believe the Midnite 150 has over-voltage protection. The 3S2P might allow you to use a much thinner wire (2awg might be overkill even with 2S). Note that you are not required to fuse/breaker strings with less than 3 parallel strings.

Use:

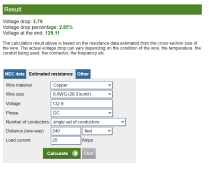

https://www.calculator.net/voltage-drop-calculator.html (Estimated Resistance tab)

To evaluate wiring scenarios. Start with the appropriately rated wire gauge and then check for voltage drop based on series Vmp and Imp. 3% is generally a good target, but for extreme situations (240' run), one might consider up to 10%. Those percentages will manifest as % power loss.

91.7A from panels is not likely. I'm guessing your panel Vmp is around 38V, so 240W/38V = 6.31A?

Maybe you meant 19.7A (3X 6.57A)?

Quick check of voltage drop using the calculator above:

3X Vmp = (240/6.57=36.5) *3 = 109.5V. Again, confirm the Classic has over-voltage protection. I'm almost certain it does.

2X Imp = 6.57 * 2 = 13.14A

8awg wire has a 3.62% voltage drop over 240 ft, 109.5Vmp and 13.14A.

The battery portion is very confusing. The way you have it sketched is as though you have 3X 24V batteries in series.

You appear to be using only one BMS to manage three batteries. That's not typical unless you're using something like a Batrium.

Better to have a BMS for each battery. That allows individual cell monitoring, and it provides redundancy.

Better to have the batteries wired in parallel.

From Victron's Wiring Unlimited in the Resources section (you should read this entire book):

Best to connect 3 as either Diagonally or Busbars

Battery disconnect on each battery. Each battery fused to busbar if you go that route.

Each inverter would get its own connection to a busbar with a fuse/breaker in the (+).

Size wires for current. Size fuses 1.25X current.

yeah but I already have 2 midnite 150 controllers...For that long run I would want the maximum voltage to reduce voltage drop and reduce the cable cost. The consequence of that is the solar charge controller would cost a lot more to handle the voltage. Victron has SmartSolar MPPT 150/35 which with a 3s2p PV configuration probably doesn't have enough Maximum PV Input Voltage for your panels, depending on where you live. You would then step up to the SmartSolar MPPT 250/70. 3s2p simplifies your wiring and reduces the cost by eliminating a three-way Y connector and the fuses and allows you to use 4 gauge wire for a 2.45% voltage drop. I used a voltage of 150, amperage of 30 and round trip distance of 480.

Please post the full specifications of your solar panels.

The downside is that your panels will be inactive until the sun has heated them to ~70°F.

Ah... you said 240W in your diagram. That's going to make a difference on voltage drop.

Yeah, sorry I fat fingered the 240

View attachment 74837

6awg per array is a 2.85% drop.

Given that your sketch has multiple errors - not just in the sketches themselves, but in the numbers (240W vs. 440W, 91.7A vs. 30A, etc.), please triple check your info before you post it. It creates confusion and extra work.

Sorry yeah I fat fingered the 240 didn’t notice that as far as the 91.7 that is the battery charging current via the midnight calculator, I did not know there was a problem with that. I am probably not talking about the right thing.The downside is that your panels will be inactive until the sun has heated them to ~70°F.

Ah... you said 240W in your diagram. That's going to make a difference on voltage drop.

View attachment 74837

6awg per array is a 2.85% drop.

Given that your sketch has multiple errors - not just in the sketches themselves, but in the numbers (240W vs. 440W, 91.7A vs. 30A, etc.), please triple check your info before you post it. It creates confusion and extra work.

Sorry, that’s not written right, it needs to be 3 24V batteries in parallel.So you show Three 24V batteries connected in series. What is your system Voltage? 72V system?