The 5-wire "main cord" is shown as a switched grounding connection in Nami's previous diagrams.

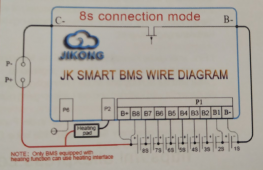

If heating pad current will be below 3A, and total power also below the limit on an 8S "25.8V" battery pack, the heating pad "ground" can be wired directly to the bundled 'main cord' of green wires. The black and red wires ARE NOT currently used at all: They are only present on the connector for a possible future power supply, to be designed JK. The heating pad "hot" connection, and any heating pad switch, should be left enabled at all times. The JK will enable the "main cord" grounding connection whenever the detected battery pack temperature has fallen below the 'minimum charging voltage' temperature setting of the BMS.

In my upcoming test configuration, using a single 4S battery of adequate size, I will be testing two ways. First, with a single "12v" heater pad connected directly from the +12v bus to this grounding cord. That test will run at slightly over 2A.

Then I will re-wire, using this switched grounding connection as the "coil" ground of a normally off (NO) automotive-type mechanical Relay. This Relay will have a "12V" coil (matching my 4S battery pack), although automotive-type Relays with "24V" coil voltage are readily available as well. An 8S "24v" battery pack would use one of those instead. In this configuration, the Relay "Load" terminals interrupt the permanently connected "hot" wire, which is driving two parallel heating pads @ 2A each, 4A total current. (The pads are permanently connected to the main grounding bus, outside of the BMS.) Use of the Relay supports higher current to the pads, through the Relay's "load" terminals, while using hardly any current at all to activate the coil. In my production configuration, I will have 3 heater pads.

Will your heater pad consume more than 3A? And, was this "verbal diagram" sufficient for you?