D

Deleted member 23531

Guest

Another interesting approach, since you are always measuring something with a large, fixed polarity (2.5V - 3.65V) would be to "subtract out" a reference voltage, allowing you to gain up the remaining difference and get higher signal before you saturate your ADC. Basically it would allow you to use your ADC's input range more fully by "zooming in" on the voltage range of interest, not wasting range on the first ~2.5V which is always present in LiFePO4 batteries.

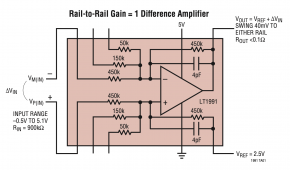

For example: you could do this using a part like this:

You'll notice it has 0.01% resistors, and a lot of them. If you hooked up your battery cell / mux output to two of those input resistors, and an appropriate reference voltage to two other input resistors, you could remove the "static" / "boring" part of the signal, and zoom in on deviation around a reference voltage (which may be 3.0V, for example).

Update: I looked at this a bit more closely and you would want to pick an amplifier like this with equal input resistors, since the battery cell voltages are centered around approximately 3.0V and that's also a common reference voltage. To use one like the LT1991 with its 3:1 resistor ratios, you would also want your battery voltage to reference voltage ratio to be 1:3 or 3:1. This isn't as common since then you would need a 9V or 1V reference voltage. It's doable; for example by dividing a 3V reference by three or multiplying up a 3V reference voltage by 3 but like I said originally, you'd have to choose an appropriate reference voltage. Unfortunately your original choice of ~4V reference doesn't have a very low lowest-common-factor with the 3V battery voltage, so that complicates the choice of resistors. To adjust the reference voltage just costs one additional low-offset op-amp.

For example: you could do this using a part like this:

You'll notice it has 0.01% resistors, and a lot of them. If you hooked up your battery cell / mux output to two of those input resistors, and an appropriate reference voltage to two other input resistors, you could remove the "static" / "boring" part of the signal, and zoom in on deviation around a reference voltage (which may be 3.0V, for example).

Update: I looked at this a bit more closely and you would want to pick an amplifier like this with equal input resistors, since the battery cell voltages are centered around approximately 3.0V and that's also a common reference voltage. To use one like the LT1991 with its 3:1 resistor ratios, you would also want your battery voltage to reference voltage ratio to be 1:3 or 3:1. This isn't as common since then you would need a 9V or 1V reference voltage. It's doable; for example by dividing a 3V reference by three or multiplying up a 3V reference voltage by 3 but like I said originally, you'd have to choose an appropriate reference voltage. Unfortunately your original choice of ~4V reference doesn't have a very low lowest-common-factor with the 3V battery voltage, so that complicates the choice of resistors. To adjust the reference voltage just costs one additional low-offset op-amp.

Last edited by a moderator: