Short_Shot

Solar Addict

- Joined

- Jul 13, 2021

- Messages

- 1,823

That's pretty much exactly what I'm using too. Just a different vendor that includes an acrylic case for an extra 2 bucks.View attachment 68459For a temperature controller I think an “inside the battery box” is a better way to go than an external controller, and it’s simpler. I used the following controller to turn the heater pads on and off…if I recall correctly they are about $5 a unit.

HiLetgo W1209, 12V DC Digital Temperature Controller Board Micro Digital Thermostat -50-110°C Electronic Temperature Temp Control Module Switch with 10A One-Channel Relay and Waterproof

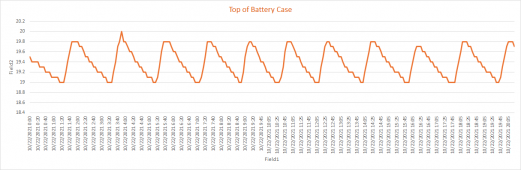

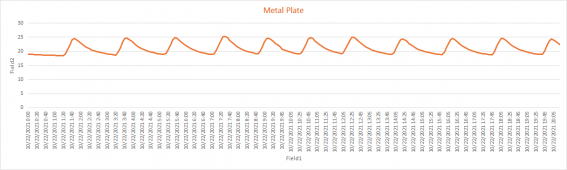

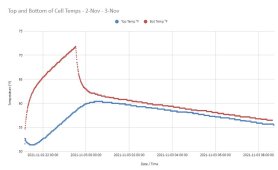

So back to the point, I'm really going to have to find a way to log the battery Temp in an appropriate location this winter. Heat it up to operating temp of 75F then turn off the heat and see how long before the bms cuts off.

My initial plan was to simply run the heats off the tow vehicle and hope the average consumption is low enough to get by for 24 hours, including running my diesel heater.

Now I'm thinking I might be able to tap some of the heat from said heater and pipe it to that side of the tongue box. It'll be much less efficient on fuel but use way less power.

I could probably blow the hot air right into the lid of the box. Bonus points if I can figure out a way to regulate it.