The build for the box I picture above is stalled. The RV is in the shop getting fixed, so I have not pulled the old battery out and put the new 2 X 8S one in.

Until I get it in front of me, I can't put the puzzle together. I do have all the parts, but don't really want to post links until I have the battery box in front of me.

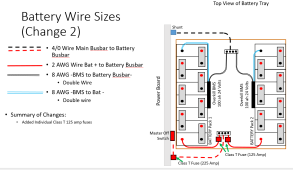

The battery box is about 24" X 24", and it turns out with 1mm neoprene and .5 mm plastic shells to protect each cell may cause the 8S as pcitured to be too big to fit in the box, so I am may build it like this:

View attachment 74047

This is the box I already have in the RV that holds 4 golf cart batteries, which will be removed and the 8S placed in it.

I posted the link but can't make a recommendation for that tray for 280 ah EVE's until mine are physically in there. Installing the sliding battery tray was a huge pain because the plastic cardboard underbody was a huge pain to remove enough to put some shoring underneath so 250 LBS of batteries did not rip out the bolts. Not only that, but the black water tank was right under one of the holes I drilled so I was luck I didn't puncture it.