You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Low temperature PV string bypass relay/switching

- Thread starter Symbioquine

- Start date

Indeed, living on the edge it seems. Panels were $140ea which was part of my motivation. That, and they fit the exact roof area on the tow vehicle and travel trailer. Rather regrettng my choice to go ecoflow for this setup now as I should have just done separates and it would have been no problem. Renogy has similar sized 320w panels in spec that fit the exact area but $640 something for a pair. (64x41" workable area or less)

The zeners temp curve show them dropping to 5W at 100C so my original thought of 12v and 5.6 would be out. But hey, the only time the protection circuit would be used would be on really cold days in which the extra heat is welcome ? A deal came up on some 250w sunpower x20 blk panels. Trying to get in on that locally. They are within spec, but for my requirements, I will need to keep the 3rd panel ground based (zero places to put it on vehicle). Just a thing I have to haul along with me now vs. out of sight out of mind. Will also keep hunting for 300+ W panels within 64x42 size.

I for sure have some thinking to do.

The zeners temp curve show them dropping to 5W at 100C so my original thought of 12v and 5.6 would be out. But hey, the only time the protection circuit would be used would be on really cold days in which the extra heat is welcome ? A deal came up on some 250w sunpower x20 blk panels. Trying to get in on that locally. They are within spec, but for my requirements, I will need to keep the 3rd panel ground based (zero places to put it on vehicle). Just a thing I have to haul along with me now vs. out of sight out of mind. Will also keep hunting for 300+ W panels within 64x42 size.

I for sure have some thinking to do.

MisterSandals

Participation Medalist

These seem like things that would confuse an MPPT unit as it seeks maximum power. Especially if these "additions" continually changed the array output.Perhaps a bank of low resistance FETs and a control circuit to turn them on/off.

One interesting idea is that it could be controlled by the voltage of the total string.... if the voltage gets close to SCC voltage limit, drop out a panel.

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

Yes..... A step function change like dropping a panel seems like it could get very confusing to the controller. The other thing that has to be thought through is when the panel should be brought back on line. If the designer is not carful the system could drop out a panel, the voltage goes down, the system sees the lower voltage and brings the panel back on line, the voltage goes up, the panels is dropped, the voltage goes down and so on. The system would need to wait till the voltage goes a lot lower than the Voc of a single panel before it brings the panel back on line.These seem like things that would confuse an MPPT unit as it seeks maximum power. Especially if these "additions" continually changed the array output.

I think a better solution would be a system that caps the voltage by draining off some of the energy but is inactive if the voltage is below the trigger voltage. Even with that, if the MPPT trys to scan past the trigger voltage it could get very confused.

Some systems have a higher 'worst case' voltage than the MPPT range. If the trigger was below the worst case voltage and above the MPPT range it might work pretty well.

Symbioquine

Solar Enthusiast

- Joined

- Jul 6, 2021

- Messages

- 427

Yes..... A step function change like dropping a panel seems like it could get very confusing to the controller. The other thing that has to be thought through is when the panel should be brought back on line. If the designer is not carful the system could drop out a panel, the voltage goes down, the system sees the lower voltage and brings the panel back on line, the voltage goes up, the panels is dropped, the voltage goes down and so on. The system would need to wait till the voltage goes a lot lower than the Voc of a single panel before it brings the panel back on line.

Yeah, these are reasons why I am skeptical of voltage based solutions - except may be the zener diode approach - since they could easily create feedback loops or oscillation. That's why I originally posed my question as a temperature based strategy.

In many places it very rarely gets cold. In those places it would be fine to just drop a panel out of the array if it gets anywhere close to cold enough - assuming such a circuit could be designed relatively cheaply and in such a way that it wouldn't take much power when it's not active. (Obviously, the location of the temperature sensor would be pretty important as well.)

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

In many places it very rarely gets cold. In those places it would be fine to just drop a panel out of the array if it gets anywhere close to cold enough - assuming such a circuit could be designed relatively cheaply and in such a way that it wouldn't take much power when it's not active. (Obviously, the location of the temperature sensor would be pretty important as well.)

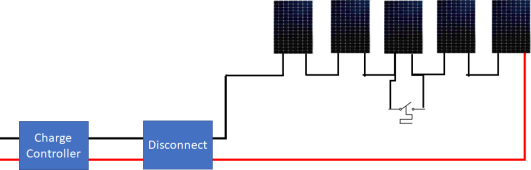

Technically, a panel can be shorted out without damaging it so in theory, you could just short one of the panels with a mechanical thermostat.

There are a few aspects that would need to be considered with this.

* The thermostat would have to be able to switch 2 x Isc or more.

* The thermostat would need to be rated to switch the full string voltage

* The thermostat would need a design where the current through it does not heat it up.

* The thermostat would need to operate at the desired low temperature.

I suspect that finding a thermostat that meets all of the requirements might be a bit of a challenge.

An alternative would be to use a thermostat that uses power from one of the other panels to power a relay.

With this, I would want to think through the early morning conditions. In dim conditions the panels can produce full Voc but very little power. You would want to think through whether the relay would be powered in time to prevent an over-voltage. I think it may be OK because the coil of the relay would be pulling down the voltage of the powering panel till there is enough power to trigger the relay.

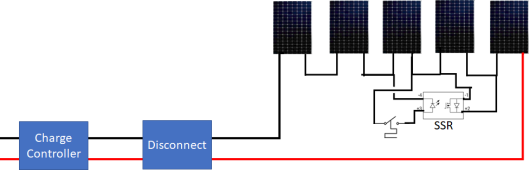

Combining the two, you might be able to use an SSR controlled by the thermostat to short a panel.

Warning: I have never done anything like this so there may be gotchas I have not thought of.

Symbioquine

Solar Enthusiast

- Joined

- Jul 6, 2021

- Messages

- 427

With this, I would want to think through the early morning conditions. In dim conditions the panels can produce full Voc but very little power. You would want to think through whether the relay would be powered in time to prevent an over-voltage. I think it may be OK because the coil of the relay would be pulling down the voltage of the powering panel till there is enough power to trigger the relay.

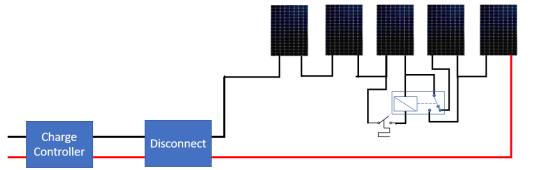

Wouldn't you just use a relay that - when (un|under)powered - defaults to the "shorted" (S-1) state? That way the failure mode for the circuit as a whole (relay contact welding aside) would be the safe one?

FilterGuy

Solar Engineering Consultant - EG4 and Consumers

That works, but then the relay has to be using power all the time to keep the panel in the circuit.Wouldn't you just use a relay that - when (un|under)powered - defaults to the "shorted" (S-1) state? That way the failure mode for the circuit as a whole (relay contact welding aside) would be the safe one?

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,632

My understanding is that the danger period is in the morning when the strings come up to voltage very quickly but there's little actual energy available, just a voltage which could possibly overwhelm the SCC input.

Sooooo. How about a FET based shunt regulator set to just below the SCC Voc limit.

I'm thinking those surface mount zeners won't be able to dissipate that power for more than a few minutes at best.

The amount of current that has to be drawn to drop voltage, and the power dissipation required, is quite high.

Maybe not when sun first comes up, but during a cold day when SCC decides it doesn't need to draw much power.

A relay or FET that shorts out one panel based on string voltage, and turns off with hysteresis, is something I've thought of.

Maybe turn off based on current. The issue is only under no-load, and once MPPT starts drawing current that pulls voltage down (about 10% for Voc - Vmp)

Similar threads

- Replies

- 2

- Views

- 230