In a few hours of reading I have found moderately discouraging info on mc4 connectors. There seem to be dozens of relatively worthless knockoffs available on Amazon, and a few possible functional but-no-promises. There are NO standards which might ensure compatibility between suppliers and even if there were, imported junk is labeled in any manner that might sell. There seem to be only two manufacturers which have certified their connector (mc4 type) products to meet certain electrical standards: Amphenol and Staubli; honorable mention to Radox and mc3 and Tyco-Solarlock. Without this certification you can only go by "do I feel lucky...". Unless you can (1) find reliable info on a brand of connectors derived from many (long term trouble free) installations; (2) that are still available; (3) that are being installed currently. Lacking any of those criteria, there is no solid assurance of quality outside the two name brands. And get this: The name brand certifications LEGALLY DEPEND on using that manufacturers "special" tools. Not just the crimpers (that's the biggee) but the wire cutters and the stripper as well.

One of the most consistent problems seems to be trivial until you need to assemble dozens, hundreds, of connections - the available wrenches don't fit most of the connectors sold. Buying the wrench from the supplier of your choice _might_ give a decent fit, but many Amazon reports state otherwise. Crapshoot. When there are dozens of connectors to assemble using general purpose hand tools becomes an annoyance; for hundreds, it becomes a real problem. I expect that a quality crimper can be found that works well, but it may take some experimentation with different tools.

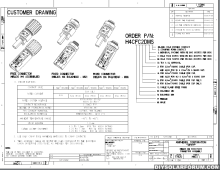

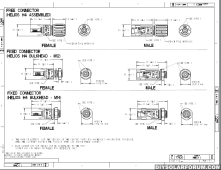

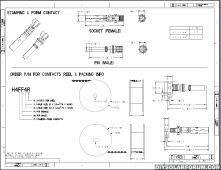

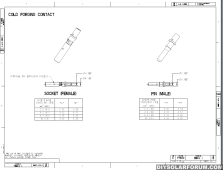

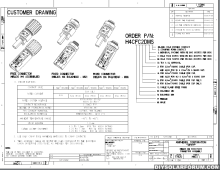

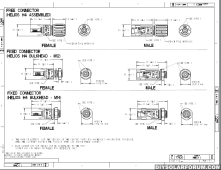

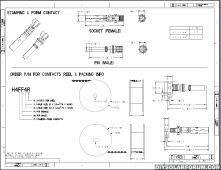

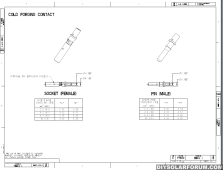

Another point to note: From Amphenol and maybe Staubli, there are at least two different types of pins which will fit into the case: a forged pin and a stamped pin. If I have read the diagrams right, the do not mix - the joining parts are different sizes.

To me, the cost of redoing problems that may have been avoided by using spendy connectors way surpasses any cost savings up front. Personal time, down-time for important loads, re-buying connectors and tools trying to find stuff that actually works, potential problems with wire length due to cutting off bad connectors, further potential delays due to weather, cost of unforeseen failures in the middle of another busy schedule. A $$$, even a few hundred $$$ more up front to avoid gambling on the truly HUGE costs possible down the line seems a no brainer to me. But even with commitment, sourcing good to excellent parts and material is not a no brainer.

I will try to load the Amphenol diagrams from Mouser. The links below are from a larger installer who has opinions about connectors based on their experience. And I'll add my usual blurb about the net: I _strongly_ advise readers that if any of the docs they find on the net even might be useful, dl them onto your local machine immediately. The net is changing daily...

Regards,

Rufus

The Cost $$ of Not Learning About Solar Connectors: Series — HelioVolta

We inspected 100s of solar systems, this is what we learned about solar connectors — HelioVolta